Today's CNC numerical control machine simulation software eliminates the need to manually verify and inspect parts in the time-consuming simulation cycle of the machining shop, but can achieve faster setup and reduce downtime. The simulation and detection of programming errors in the process, potential collisions between machine tool components and other inefficient areas (including the optimal cutting speed) can be simulated and tested and discovered in advance.

In view of the current situation in 2020, in an industry full of supply chain issues, demand shifting, milling and machining work outsourcing and other challenges, maintaining a competitive advantage and profitable machine shop is unstable, as well as labor shortages/skills gaps.

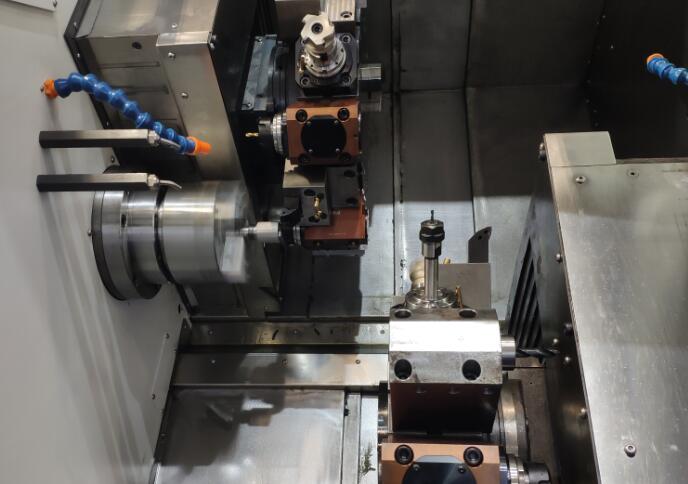

And programming errors usually lead to serious consequences-from damage to the part to the tool hitting the workpiece, destroying the expensive spindle, and even worse, damaging the expensive equipment. All of this leads to costly downtime, production delays and lost revenue. The use of CNC machine simulation software solves this problem and is an important tool for machinists to ensure that the CNC program is programmed accurately and the part is processed correctly the first time. Now, advances in software development make it possible to simulate all parts and operations of CNC machine tools, and interactively display the material removal process of the CNC program. In order to break down its utilization, the machine operator inputs the applicable CNC program, the geometry of the part, the tool used, and other applicable parameters, and then runs it.

If you'd like to speak to a member of the Anebon team for custom precesion turned parts, please get in touch at info@anebon.com

Post time: Nov-11-2020