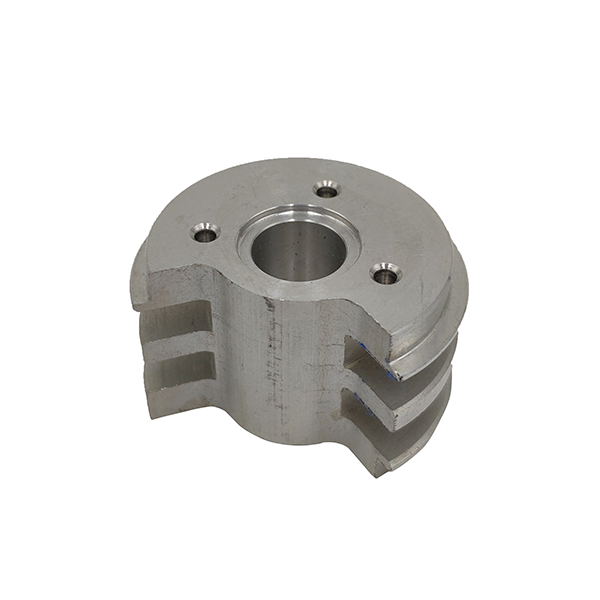

Hot Selling for Custom Metal Manufacturing - CNC Turning Parts Used For Medical Equipment – Anebons

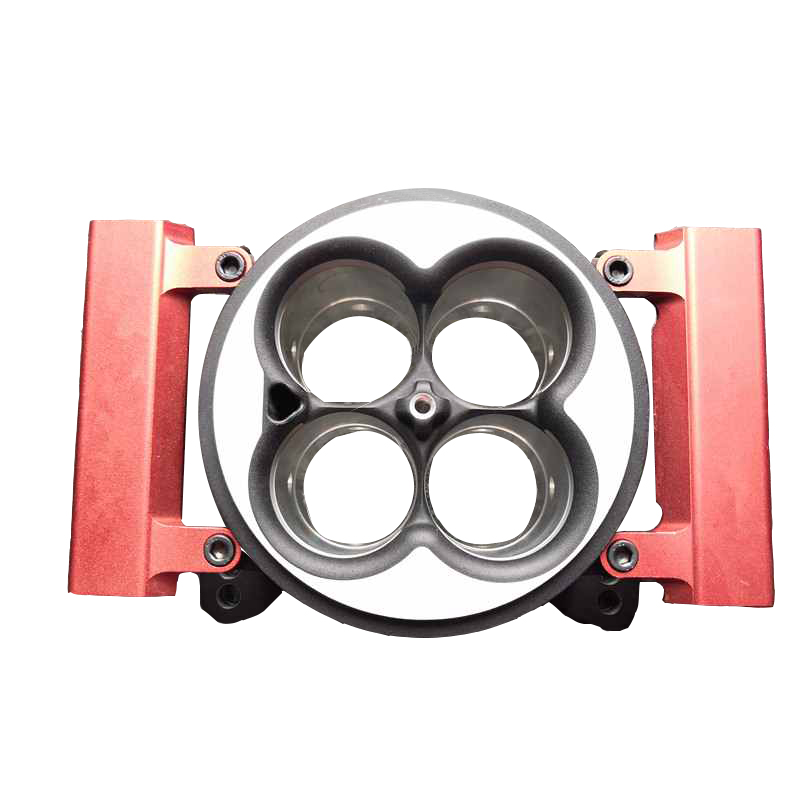

Every member of our large efficiency profit team values customer requirements and organizational communication. Factory supplies stainless steel/steel alloy CNC machined parts, medical machine parts, precision turning and milling parts, inspired by the rapid development of automotive, medical and consumer parts.

| Item Name | CNC Turning Parts Used For Medical Equipment |

| Available materials | Aluminum: Aluminum 2024 Aluminum 5052 Aluminum 6061-T6 etc.Stainlesss steel : UNS S32304 UNS S32003 UNS S31803 UNS S32205 etc. |

| Tolerance | 0.005mm~0.1mm |

| Surface Roughness | Ra 0.8-Ra3.2 |

| DRW format | .jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Equipment | CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, CNC Punch Press Machines, Wire cutting machine, High-speed Stamping Machines etc. |

| Capacity | According to the Parts |

| MOQ | According to your drawings |

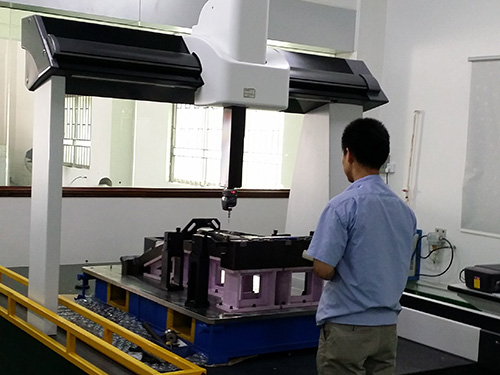

| QC System | 100% inspection before shipment, product OK rate 99.8% |

| Payment term | T/T |

|

Machining service |

Metal lathe services |

Rapid prototyping services |

|

Metal cnc services |

Metal machined parts |

Sheet metal services |

|

Metal fabrication parts |

Metal machining videos |

Titanium prototyping |

1.Can you produce precise parts according to our drawing or our samples?

Yes, we can produce parts according to your 2D or 3D drawings, and we can make measurement for your samples to make drawings for production.

2.What is the quality guarantee?

We will make 100% inspection before packing and delivery to make sure the products 100% meet your requirements.

We will keep the production drawing and test report with 3 months, if you found any problems when received the parts, please contact with us at the first time, we will give you a solution within 8 hours.

3.How do you guarantee the deliver time?

We have independent PMC department to arrange the production plan.

We have production meeting every morning to report the production progress and discuss the problems.

We will make production progress report to you every week and take some pictures for your reference, that’s you can know our production progress clearly.