Factory directly China Cnc Manufacturing - CNC Milling Auto Parts – Anebons

We provide buyers with the ideal high quality products and important company support. As a professional manufacturer in this field, we have now received practical experience in the production and management of OEM/ODM supplier Cnc machined aluminum body custom aluminum Auto parts, mechanical parts, quickly enhanced, our customers from Europe, USA, Africa and the world All over the place.

OEM / ODM suppliers aluminum alloy parts, CNC machining aluminum parts, custom precision aluminum parts, with strong technical strength and advanced production equipment, as well as staff purpose, professional, dedicated entrepreneurial spirit. Our company has passed ISO 9001:2015 international quality management system certification, EU CE certification; CCC.SGS.CQC other related product certification.

| Place of Origin | Dongguan,China |

| Style | Nonstandard parts |

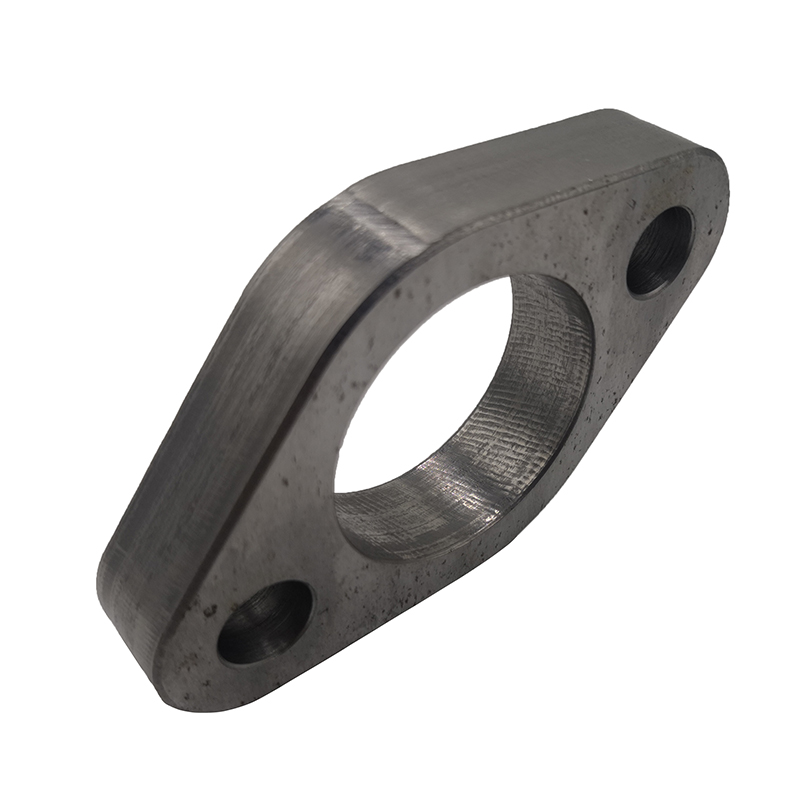

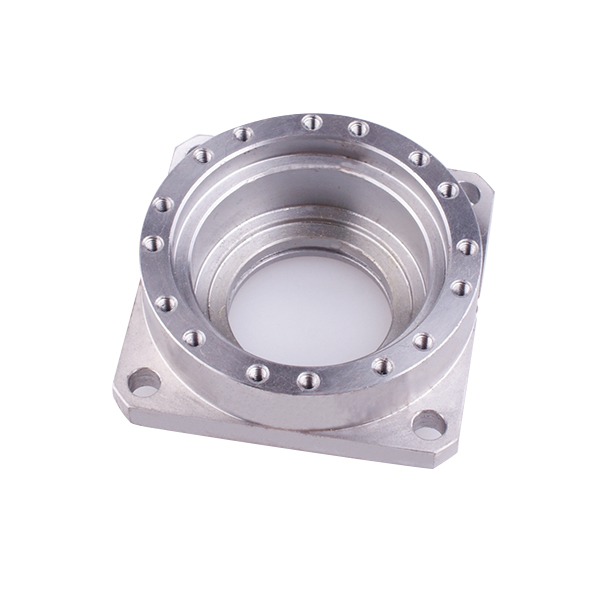

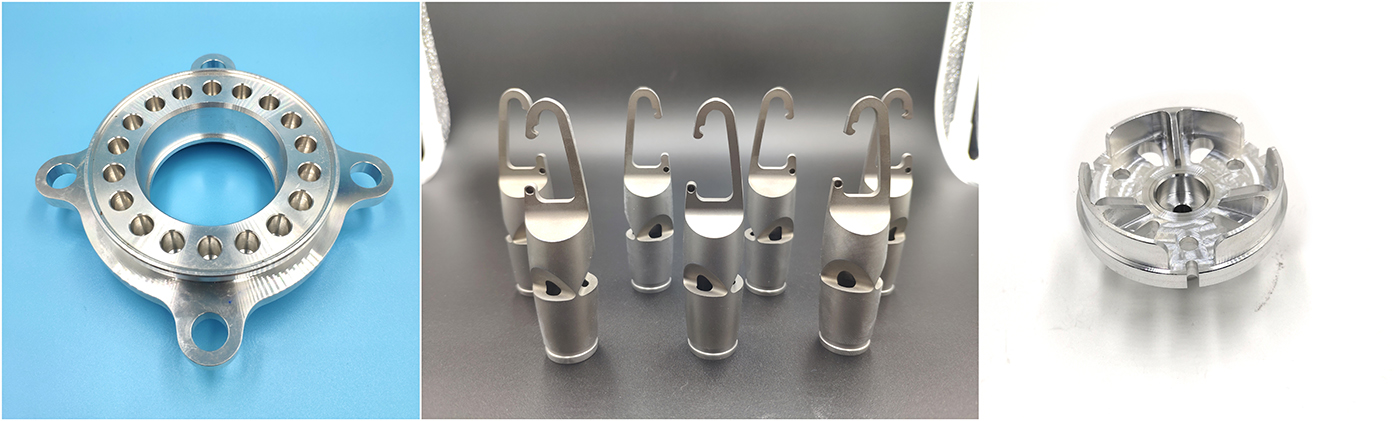

| Material | Iron, Stainless Steel, Brass, Al, Copper, etc. (according to customer‘s demands) |

| Process | CNC, cleaning and packing |

| Finish | Plating (Zinc, Nickel, Chrome, Tin, Silver ,Copper,Gold ); Eletroplating, Anodizing, Heat treatment, Black oxid |

| Used For | Automatic,medical equipment,thermostat, Communication Equipments electrical appliance and Photo electricity Equipments |

| Main Equipment | CNC turning machines/Automatic lathes machines |

| Package | According to customer‘s requests |

| Advantages | One stop production, high quality, precision tolerance control, inspection service, earth-friendly hardware, experienced team |

| Certificate | ISO9001:2015 |

|

cnc lathe axis |

cnc milling |

cnc services near me |

|

cnc lathe services |

cnc milling aluminum turning metal parts |

cnc stainless steel machining |

|

cnc lathes |

cnc milling engraving |

cnc steel |

1.ODM&OEM service are all welcomed

2.Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

3.Small orders accept

4.Reasonable and competitive price according to your drawings

Quality Control:

1) Technicians self-check in production

2) Engineer spot check in production

3) QC inspects after mass production finished

4) International sales who were trained the technical know-how spot check before shipping