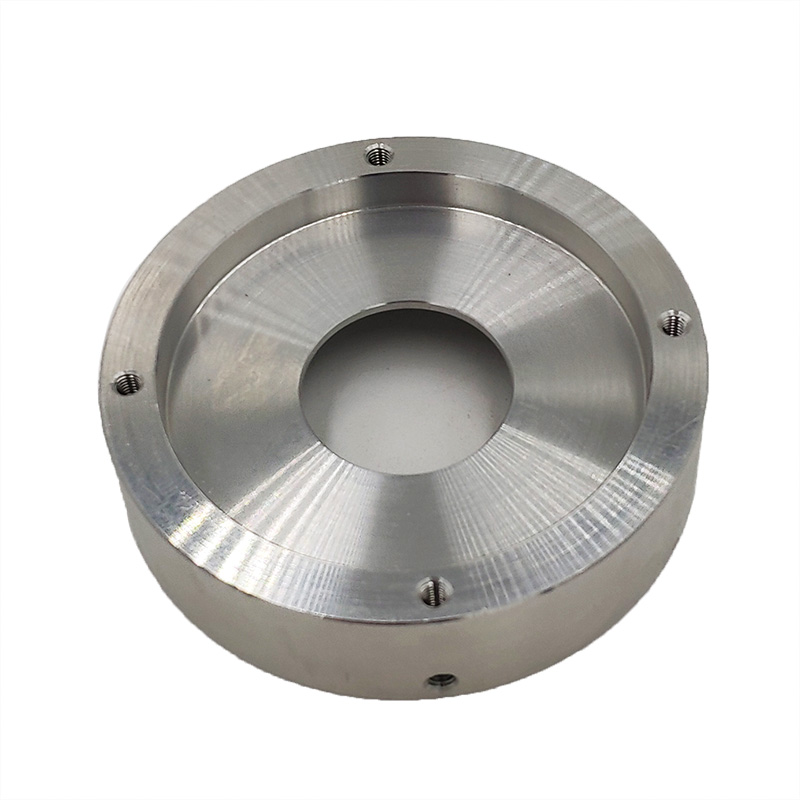

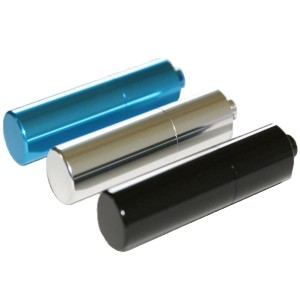

CNC Precision Hardware Turning Service

Which parts are suitable for precision machining?

First of all, hardware machining. Compared with ordinary lathes, CNC lathes have the function of constant linear speed cutting. Both the end face of the car and the outer circle of different diameters can be processed at the same linear speed. The machining of mechanical molds guarantees the surface The roughness values are consistent and relatively small. The ordinary lathe has a constant speed, and the cutting speed is different for different diameters. When the material of the workpiece and the tool, the finishing allowance and the tool angle are certain, the surface roughness depends on the cutting speed and feed rate.

How to improve the machining effect of machining?

1. In the process of using the speed-controlled machine tool for processing, it is necessary to ensure that the work surface can bear the most sufficient weight and the machining price to ensure that the machining process can proceed smoothly. Modern processing is to be able to increase production. If the processing table cannot meet the requirements of use, Anebon metal machining will be affected to a certain extent in the production process. 2. In the process of machining, due to the increasing speed of modern high-speed cutting, in order to adapt to the machining method, the only way to reduce the radius of the tool is to increase the moving speed of the main bearing of the machine tool. Meet the use requirements in the processing process and improve the quality of use.

We divide mechanical processing into the following 3 stages:

1, Face before hole

For parts such as box body, bracket and connecting rod, the plane should be processed first and then the hole should be processed. In this way, the holes can be positioned on the plane to ensure the position accuracy of the plane and the holes, and it is convenient to process the holes on the plane.

2. Process the datum surface first

During the processing of the part, the surface as the positioning reference should be processed first in order to provide a precise reference for the subsequent processing as soon as possible. It is called "benchmark first row".

3, Divide the processing stage

Surfaces with high processing quality requirements are divided into processing stages, which can generally be divided into three stages: rough processing, semi-finishing and finishing. Mainly to ensure the processing quality; facilitate the rational use of equipment; facilitate the arrangement of the heat treatment process; and facilitate the discovery of blank defects, etc.