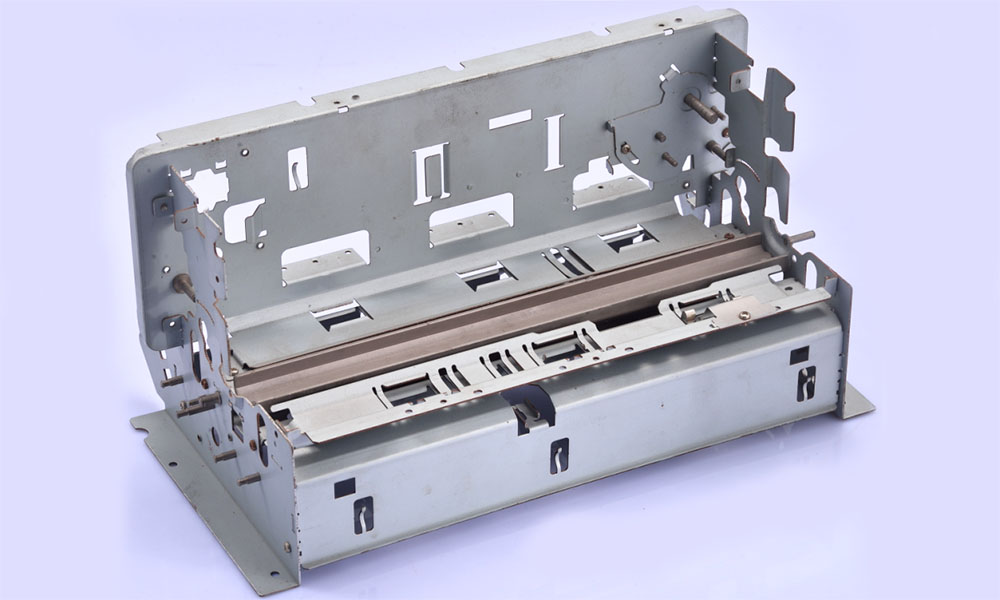

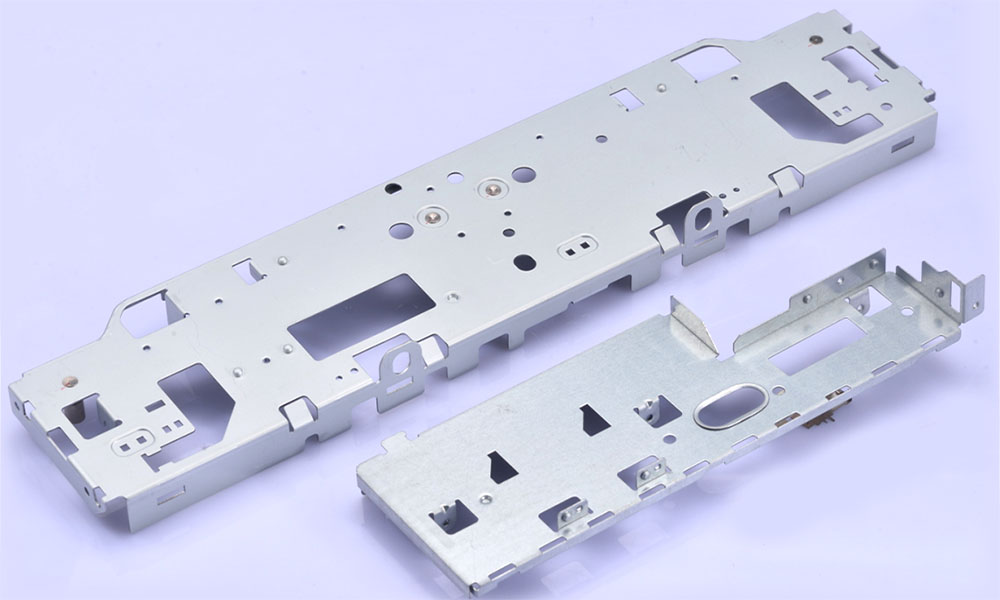

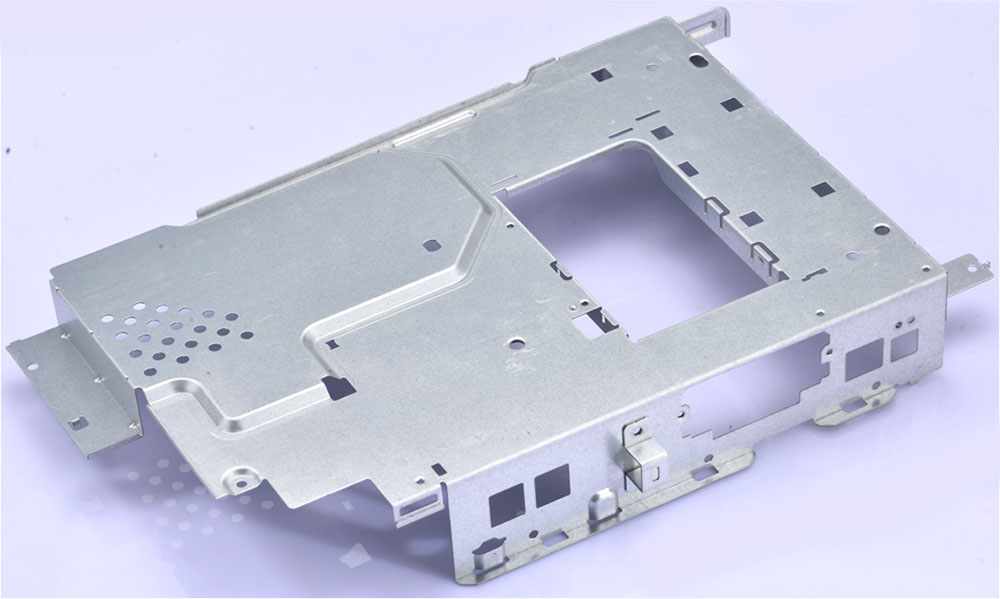

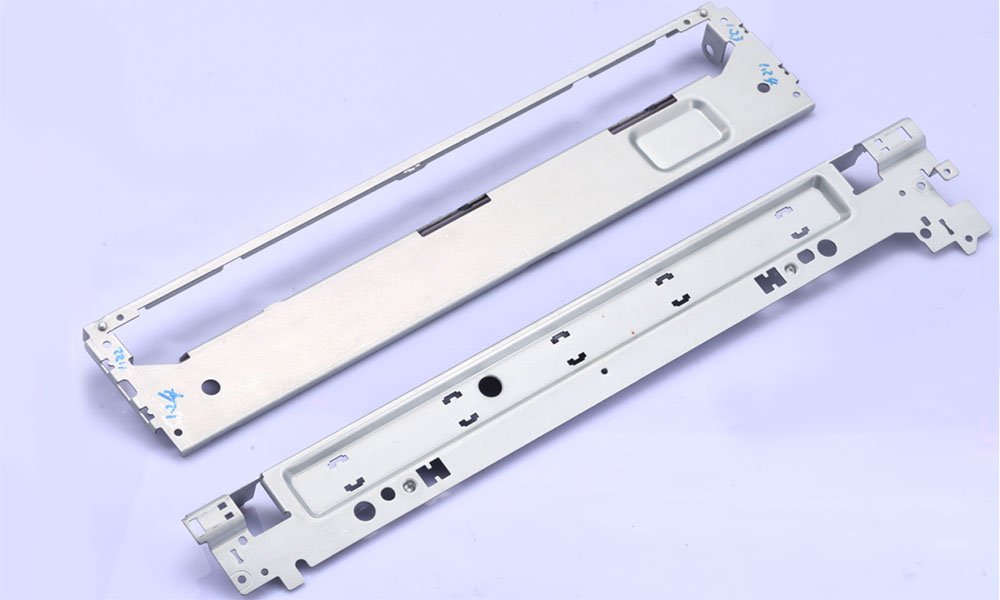

Ukugxiviza kwensimbi okwenziwe ngokwezifiso kwe-Anebon kufaka phakathi ukubhoboza, ukugoba, ukwelula, ukufaka imbossing nokunye ukusebenza. Inqubo ngayinye yenziwa kusetshenziswa amathuluzi aklanywe yi-CAD/CAM anganikeza ukunemba okudingekayo kwezingxenye eziyinkimbinkimbi. Ukugxiviza kwensimbi yeshidi kuyindlela esheshayo nephumelelayo yokukhiqiza izingxenye eziqinile, zekhwalithi ephezulu zehadiwe, i-aerospace, yezokwelapha, ye-electronics, yezimboni, izibani nezinye izimboni.Sizosebenzisa amathuluzi ethu athuthukile kanye nethimba elinolwazi ukwenza ngokwezifiso imikhiqizo oyicabangayo, futhi sikholelwa ukuthi singahlangabezana nezidingo zakho kokubili ngokwenani nekhwalithi.

Singanikeza izinketho ezilandelayo zokukhiqiza:

Izinsimbi zensimbi

Izingxenye ezijulile

Izingxenye ezihlanganisiwe

Ukwenza amathuluzi

Ukubhoboza, ukuthepha nokulungisa kabusha

Spot and projection welding

I-CO2 welding - manual kanye ne-robotic

Metal Stamping Process

Nakuba ingashintshwa ukuze yakhe izingxenye ezithile, ukugxiviza kwethu kwensimbi kuvame ukulandela izinyathelo ezinhlanu ezifanayo:

Isibuyekezo sedizayini:Onjiniyela bethu bazobuyekeza ingxenye yedizayini ngokuningiliziwe ukuze baqinisekise ukuthi ifanele ukugxivizwa kwensimbi. Lokhu kuhlanganisa ukuhlaziywa okujulile kwezingxenye zobukhulu, izinto zokwakha, izilinganiso ezinwetshiwe kanye nokubekezelelana okudingekayo.

Cindezela Ukukhetha:Onjiniyela bethu bazonquma usayizi womshini ofaneleka kakhulu nobubanzi bosayizi wengxenye nezinto ezibonakalayo.

I-3D Virtual Prototype:sebenzisa isofthiwe ebonakalayo ukuze udale ama-prototypes ezingxenye. Ngaphambi kokuthi inqubo yokukhiqiza iqale, i-prototype iqhutshwa ngenani elikhulu lezifaniso zokusebenza ukuze kutholwe noma yiziphi izinkinga zedizayini.

Ukusethwa kwesisetshenziswa:Onjiniyela bethu abanekhono bahlola usayizi kanye nezidingo zezingxenye futhi bamise izinto zamathuluzi.

Inqubo:Faka insimbi yensimbi noma insimbi ingenalutho esikhunjeni bese uyilungisa. Bese uvula umshini wokucindezela bese uqala ukusebenza ngamandla asebenzayo. Phinda inqubo kuze kube yilapho ingxenye ifinyelela usayizi oyifunayo kanye nesimo.

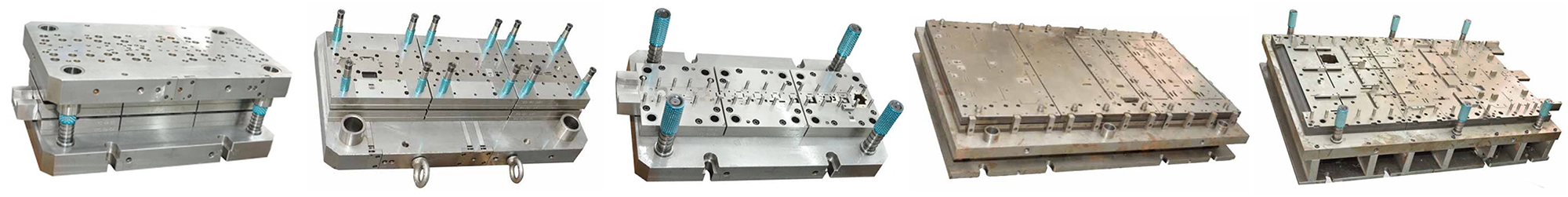

Ukwenza Isikhunta

Ukwakhiwa nokukhiqizwa kwamathuluzi okuqhubeka nokunemba kuyingxenye yesithembiso sokuletha isisombululo esiphelele sokukhiqiza sokukhiqiza izingxenye zensimbi ezicindezelwe.

Namuhla, sisebenzisa ubuchwepheshe bethu bangaphakathi ukuze sinikeze ngamasevisi esikhunta anembayo angabizi kakhulu.

Singahlehlisa ukuklama umkhiqizo noma umdwebo wobunjiniyela be-CAD ukuze sikhiqize ithuluzi lomshini elingakhiqiza umkhiqizo wakho. Amathuluzi esikhunta aqinile kakhulu futhi anokwethenjelwa, anomjikelezo wempilo ende, ngakho-ke izindleko zingathathwa njengokutshalwa kwezimali.

Ithuluzi lesikhunta lizoba ngelakho, kodwa singagcina, silungise futhi silungise lapho kudingeka.

Sheet Metal Fabrication

Njengesitolo esiphelele samathuluzi kanye nesitolo sokufa, sinekhono kuzo zonke izindawo zokwenziwa okuhlanganisa i-fiber laser, i-CNC punching, ukugoba kwe-CNC, ukwenza i-CNC, ukushisela, ukukhanda kwe-CNC, ukufakwa kwehadiwe kanye nokuhlanganisa.

Samukela impahla eluhlaza kumashidi, amapuleti, amabha noma amashubhu futhi sinolwazi lokusebenza ngezinto ezihlukahlukene ezifana ne-aluminium, ithusi, insimbi engagqwali nezinsimbi ze-carbon. Ezinye izinsiza zihlanganisa ukufaka ihadiwe, ukushisela, ukugaya, ukukhanda imishini, ukujika nokuhlanganisa. Njengoba umthamo wakho ukhula siphinde sibe nokukhetha ukusebenzisa izingxenye zakho kanzima ukuze zisebenze emnyangweni wethu wokugxiviza ngensimbi. Izinketho zokuhlola zisukela ekuhloleni izici ezilula kuze kube yi-FAIR ne-PPAP.

Imikhiqizo Yethu