Umgomo wokusebenza we-polygon processing

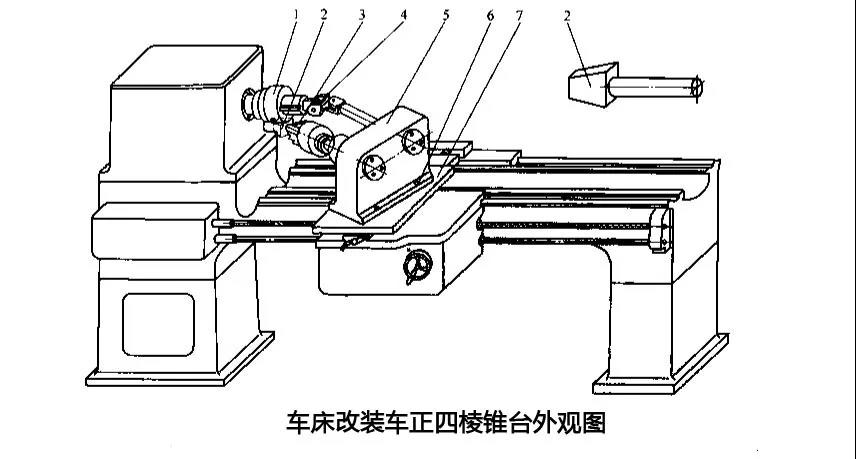

Ukucubungula ama-workpieces e-polygonal ku-lathe, idivayisi ekhethekile njengoba kukhonjisiwe emfanekisweni idinga ukufakwa.

I-1-Cutter 2-Workpiece 3-Chuck 4-Universal coupling 5-Transmission 6-Screw 7-Bottom plate

Uma ujika, ufakwa epuleti lesilayidi elimaphakathi ukuze wenze ucezu lokusebenza nethuluzi lijikelezise ohlangothini olufanayo, futhi ubudlelwano besilinganiso sesivinini phakathi kwethuluzi nendawo yokusebenza enenani elithile lamakhanda amathuluzi kusetshenziswa ukuze kubonakale ukunyakaza okuhlobene ithuluzi kanye ne-workpiece, ukuze ibonakale ngokuvumelana nomthetho wokuthuthukiswa kokwakhiwa kwe-Surface, qedela ukucutshungulwa kwesikwele, i-hexagon, unxantathu ovamile, i-trapezoid, isigubhu, ukhalo, isicaba, idayimane, i-polygon engavamile kanye umsebenzi we-polygonal nge-taper.

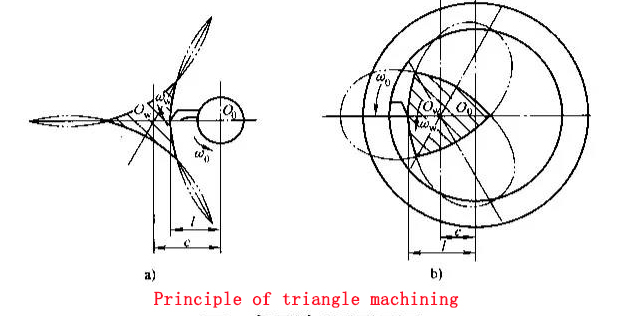

Isibonelo, lapho ucubungula unxantathu olinganayo, isilinganiso sokudlulisa ithuluzi ku-workpiece i-i = 3, ngakho-ke umkhondo wethiphu yethuluzi elihlobene ne-eksisi ye-workpiece iyijika elivaliwe eliphindaphindiwe ngezikhathi ezithile ngesikhathi sokusika, futhi ingxenye emaphakathi ezungezwe ijika yenza unxantathu ocishe ube ngunxantathu.

Uma i-eksisi ye-workpiece ingaphandle kwesiyingi sokunyakaza kwethiphu yethuluzi, unxantathu obizwa ngokuthi "indlela yokusika yangaphandle" uboniswa kuMfanekiso a; uma i-eksisi ye-workpiece ingaphakathi kwendilinga ye-tip motion motion, ibizwa ngokuthi "indlela yokusika yangaphakathi", futhi unxantathu uvela njenge-Figure b ibonisa.

Ingabonakala ngezibalo ezingunxantathu eziveziwe, kungakhathaliseki ukuthi indlela yokusika yangaphandle noma indlela yokusika yangaphakathi isetshenziswa, izindawo zokusebenza ezicutshungulwayo ezingunxantathu azisicaba, kodwa ziwubuso be-arc obuyindilinga cishe obuyisicaba. Ngakho-ke, indlela yokuguqula amapholygoni okukhulunywe ngawo ngenhla kuphela Ingasetshenziswa ekucubunguleni okungadingi ukuphakama okuphezulu kwendawo.

2 Ukwethulwa kwamathuluzi asetshenziswa kakhulu

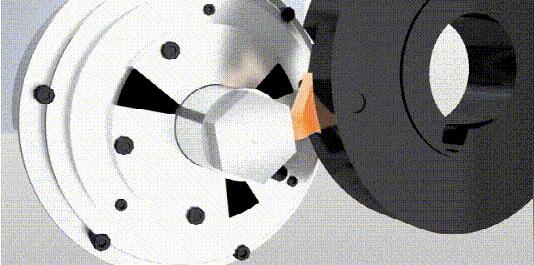

Isingeniso esingenhla siyithiyori yendabuko, futhi ekusebenziseni okungokoqobo kunezinhlobo ezahlukene zokwethulwa kwamathuluzi, isimiso siyefana, kodwa ekwethulweni komgomo, ithuluzi lenza ukunyakaza okuyinhloko ku-spindle, i-workpiece yenza ukunyakaza okuyisizayo. , futhi Ekusetshenzisweni okungokoqobo, i-workpiece inyakaziswa kakhulu ku-spindle.

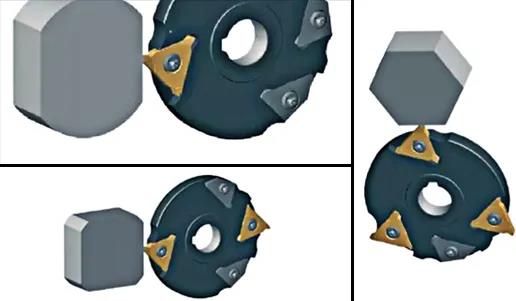

Ekuphenduleni i-polygon, i-flying cutter disk isetshenziselwa ukusika amapholygoni (izinhlangothi ezintathu kuya kweziyisishiyagalombili) ohlangothini lwe-axisymmetric workpiece. Ucezu lomsebenzi (oluphothayo oluyinhloko) nethuluzi elijikelezayo (ikhanda lokusika elindizayo) zisebenza ndawonye ngendlela ehambisanayo ukuze kusetshenziswe indawo yokusebenza.

Inani lezindawo ezisikiwe lincike esilinganisweni sokudlulisela kanye nenani lemiphetho yokusika ethuluzini lokusika. Isiqondiso sokujikeleza kwe-workpiece kanye nethuluzi liphambene.

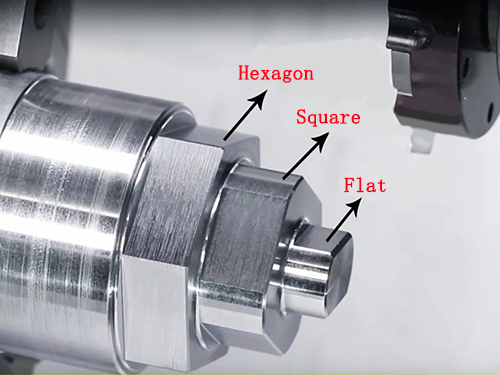

Icubungula ama-Hexagon

Icubungula unxande

I-cutter enama-blade amabili isetshenziselwa ukusika ama-quadrilaterals, futhi i-cutter enama-blade amathathu isetshenziselwa ukusika ama-hexagon, njll. Uma izilinganiso ezihlukene zokudlulisela zisetshenziswa noma inani lemiphetho yokusika yethuluzi lishintshiwe, ukucindezelwa okukhulu noma ukuphambuka okuphuma phambili. ama-arcs angase avele phezu kwendawo yokusebenza.

Ngenxa yalesi simiso, i-trajectory yohlaka ekhiqizwe iphuzu eliyiphuzu ifana ncamashí ne-ellipse, kodwa ijika elisetshenziswa endaweni yamandla e-wrench liyingxenye ye-ellipse ene-radius enkulu yokugoba, ngakho-ke ayithinti ukuhlanganisa ukuqinisa nokukhulula. ukusebenza.

We are a reliable supplier and professional in CNC service. If you need our assistance please contact me at info@anebon.com.

Isikhathi sokuthumela: Apr-29-2020