1. Ikhono elihle lenqubo. Lapho sithola umdwebo womdwebo wokucubungula ingxenye engumshini, kufanele sisheshe sisebenze ubuchwepheshe bokucubungula lo mdwebo engqondweni yethu, kusukela kumishini yokucubungula, amathuluzi, izinto ezilungiswayo, ukuhlola izinto ezilungiswayo kuya ezindlekweni zokucubungula Lezi zinyathelo zinezinqumo eziyisisekelo, futhi lezi. izahlulelo kumele zibe izahlulelo eziqondile ezisuselwe ekhonweni lakho lobungcweti kanye nolwazi lwakho lomsebenzi. Ukuthuthukisa ikhono elihle lenqubo, ngaphezu kolwazi lobuchwepheshe bokucubungula, kuyadingeka futhi ukuba nokuqonda okuphelele kwemikhiqizo ehlanganiswe izingxenye ezicutshunguliwe, ngoba izidingo zokucubungula zengxenye kufanele zenziwe ngokusekelwe ezidingweni zomhlangano. yomkhiqizo Yebo, onjiniyela abaningi abancane bokuklama abanakho ukuqwashisa okunjalo lapho benza ingxenye ethile, ngakho-ke unjiniyela wezinqubo ezinhle akufanele nje achaze ubuchwepheshe bokucubungula ingxenye enengqondo yomkhiqizo, kodwa futhi abe nekhono kanye nokuqwashisa ukushintsha nokwenza ngcono umklamo Ukuchezuka konjiniyela kusetshenziselwa ukuthuthukisa inqubo yokukhiqiza imikhiqizo kusukela ekucabangeni kwengxenye yesakhiwo, ukwethembeka kokukhethwa kwempahla, ukunemba kokubekezelela ukuqondanisa, kanye nokunciphisa izindleko zokukhiqiza. Eqinisweni, leli inani elikhulu kakhulu lonjiniyela bezinqubo zemishini.

2. Ujwayelene nezinto zokusebenza zeshabhu yakho yokusebenzela. Engikushoyo ngokujwayela kusho ukuthi kufanele ujwayelane namakhono okucubungula kanye nobubanzi bemishini ehlukahlukene yokucubungula endaweni yakho yokusebenzela, nokuthi hlobo luni lokunemba kokucubungula abangakuzuza.

1) Amakhono okwenza imishini, hlobo luni lwemishini yokucubungula indawo yakho yokusebenzela enayo? Isibonelo, ukuguqula, ukugaya, ukuhlela, ukugaya, ukubhoreka, ukubhoboza namanye amathuluzi omshini, hlobo luni lwezinqubo zokucubungula izingxenye ezifanele ukucubungula, ungathola umdwebo Ungaqinisekisa ngokushesha izinqubo zokucubungula zale ngxenye nokuthi yiziphi izinto ezidingekayo. ukuqedela lezi zinqubo zokucubungula, bese uqhathanisa okokusebenza okukhona endaweni yakho yokusebenzela ukuze wenze isinqumo sekhono lokucubungula. Lona unjiniyela ofanelekayo wokucubungula imishini kufanele abe nawo Ngasikhathi sinye, uma ingekho imishini yokucubungula ehambisanayo yokuqedela ukucutshungulwa kwengxenye, kufanele sicabangele ukuthi singakwazi yini ukunweba uhla lokucubungula lweminye imishini ekhona ngokusebenzisa amathuluzi akhethekile noma amathuluzi okusika. . Lokhu okonjiniyela omuhle wenqubo Kubuye kube isihloko esiyinselele kakhulu. Ezimweni eziningi, inqobo nje uma singayeki, kuhlale kunezindlela eziningi zokuxazulula inkinga kunobunzima.

2) Ibanga lokucubungula, ikakhulukazi libhekisela ekucutshungulweni kwemishini yokucubungula endaweni yakho yokusebenzela, ngoba nakuba izinhlobo eziningi zemishini zifana, zinezincazelo kanye nosayizi. Uhla lokucubungula lwemishini emikhulu ngokwemvelo lukhudlwana. Uma uwuthola Lapho udweba umdwebo, kufanele usheshe unqume ukuthi imishini yokucubungula endaweni yakho yokusebenzela iyakwazi yini ukucutshungulwa ngokwezilinganiso zohlaka lomdwebo. Masingaxoxi ngokunemba kokucutshungulwa, okungenani uqinisekise ukuthi ukushaywa kokucubungula kufanele kufake usayizi wengxenye. Eqinisweni, mayelana nobubanzi bokucubungula, sisengakwazi ukufeza ukucutshungulwa kwezinye izingxenye ezicutshunguliwe ezedlula ukushaywa kwensiza ngokufaka okukodwa, ukugoqa okubili, nokuma kwesisekelo sendawo. Isihluthulelo siwukuba nesibindi kubuchwepheshe bokucubungula izingxenye. Ukuqamba kanye nokuphumelela.

I-3) Ukunemba komshini, kufanele ube nokuqonda okuhle kakhulu kokunemba kokucubungula kwemishini yokucubungula endaweni yakho yokusebenzela, hlobo luni lwemishini engafinyelela ukuthi yikuphi ukunemba kokucubungula, ikakhulukazi ngokwezidingo zemidwebo ukuze kuzuzwe ukunemba kokucubungula okuhambisanayo, lokhu Ibaluleke kakhulu, ngaphandle kwalokho ngeke ukwazi ukuqedela ukwamukela kwekhasimende ikhwalithi yakho yokwenza imishini. Uma ukunemba komshini wethuluzi lomshini kuphambukisiwe, unjiniyela wenqubo yemishini onolwazi angakwazi ukulungisa indlela yokubamba ye-workpiece ngomthetho wokuphambuka wokunemba komshini wethuluzi lomshini Ukucubungula ngesinyathelo ngesinyathelo kanye nokuhlolwa okuningi ukuze kuzuzwe ukucutshungulwa okusebenzayo. yezingxenye. Yiqiniso, le ndlela yokucubungula iyindlela yokugcina ngaphansi kwezimo ezikhethekile. Okokusebenza okunokuchezuka okunembayo, kusadingeka

Ukulungisa nokugcinwa ngesikhathi esifanele kuyinkosi, kodwa unjiniyela wezinqubo ezinhle kufanele aguquguquke futhi ahluke. Bazohlala beyisisekelo nokuqiniseka kwenqubo yokucubungula izingxenye. Abasebenzi baseworkshop badinga ukumbona kuphela. Uma uzizwa uncike, uyazi ukuthi yonke into ilawulwa.

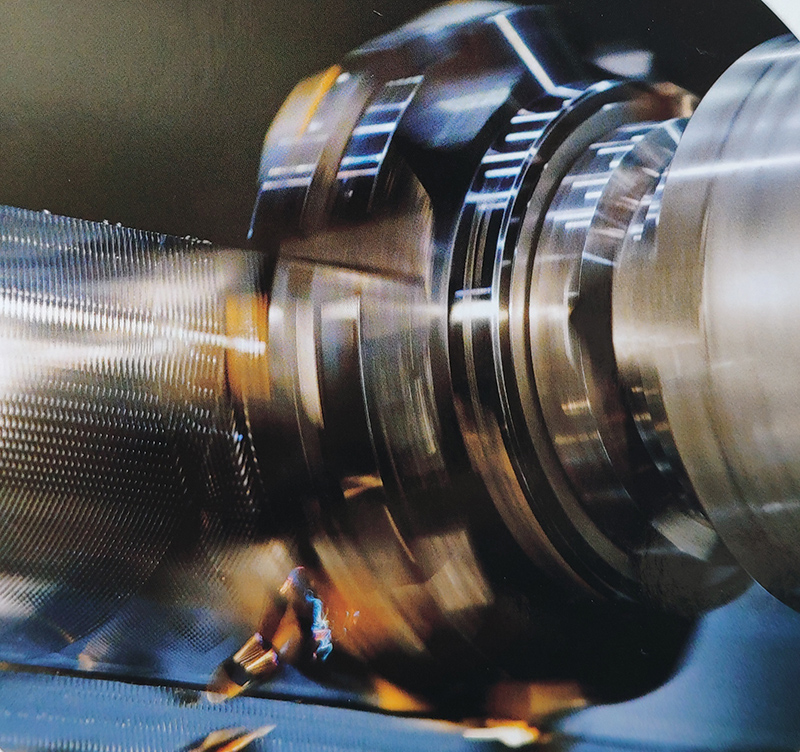

3. Amathuluzi omshini, uhlobo luni lwamathuluzi asetshenziselwa ukucubungula ukuthi yiziphi izinto zokwakha, isiphi isivinini sokucubungula kanye nezinga lokuphakela okuhlonyisiwe, noma ngabe ukupholisa kuyadingeka, futhi kufanele kube nezinqubo ezihambisanayo zomshini onzima, u-semi-finishing kanye nokuqeda. Ukuguqulwa kwamathuluzi kanye nemingcele yokucubungula akumele kuqinisekise ikhwalithi yokucubungula kanye nokusebenza kahle kokucubungula, kodwa futhi kucabangele izindleko zokucubungula, ngoba lokhu kuhlale kuwukuziphatha kwebhizinisi, futhi akulungile ukusebenza ngaphandle kwenzuzo, futhi ukukhethwa kwamathuluzi kungukuziphatha. enkulu kakhulu. Ulwazi, ngoba luhlobene eduze nezindleko zokukhiqiza izingxenye. Ithuluzi elihle alikwazi nje ukuthuthukisa izinga lokucubungula nokusebenza kahle kwezingxenye, kodwa futhi liqinisekisa ngokuphumelelayo ukuzinza nokuqina kwethuluzi lomshini. Ngesikhathi esifanayo, ingaqinisekisa ngokuphumelelayo umjikelezo wokukhiqizwa kwengxenye futhi Ukukhetha Okunengqondo kuyikhono eliyisisekelo lonjiniyela wenqubo, futhi kuyikhono elibulalayo likanjiniyela wezinqubo. Ngokwezinga elikhulu, leli khono linikezwa ngemali, ngoba kuphela ngemva kokuhlolwa kwethuluzi elikhulu kanye nokuqoqwa kokucubungula umuntu angakwazi ukwakha isipiliyoni sakhe siqu, kanye nezindleko zayo Ukuphakama nobude bomjikelezo kuyethusa futhi kuyethusa.

4. Ukulungiswa kwemishini, ngokusho kokuma kwezingxenye kanye nezidingo zokunemba kwemishini, ukuklama okujwayelekile noma okukhethekile okucutshungulwa. Izifundo eziyimpoqo namakhono adingekayo kuwo wonke unjiniyela wokucubungula imishini. Ukulungiswa okuhle akukwazi nje ukuthuthukisa ukusebenza kahle kokucubungula kwezingxenye, kodwa futhi kakhulu Ukuthuthukiswa kokunemba komshini wezingxenye kungase futhi kwandise ububanzi bokucubungula amathuluzi omshini futhi kunciphise izindleko zokucubungula izingxenye. Ikakhulukazi ngokuthuthuka kwesayensi nobuchwepheshe, ikakhulukazi ukuthuthukiswa okusheshayo kobuchwepheshe bokulawula ugesi, isisetshenziswa samanje samathuluzi siye kancane kancane Siqhubekela phambili siqonde ku-automation, sihlangene nokwakhiwa kwezinhlelo ze-pneumatic kanye ne-hydraulic, ngokusebenzisa izakhi zikagesi, isethi yezinto ezizihambelayo ezisebenza ngobuchwepheshe isiphenduke insiza ejwayelekile enqubweni yesimanje yokwenza imishini, ikakhulukazi emikhiqizweni ecutshungulwe ngobuningi, kanye nenani elikhulu lezinhlelo zokusebenza ezidinga ukulungiswa okuzenzakalelayo , Lokhu akugcini nje ngokuthuthukisa kakhulu ukusebenza kahle kokuphoqa abasebenzi, kodwa futhi kunciphisa kakhulu amandla okusebenza kwabasebenzi, kuthuthukise indawo yokusebenza, futhi kuthuthukise nokuphepha kokusebenza. Ngesikhathi esifanayo, futhi inesiqinisekiso esihle sekhwalithi yezingxenye.

5. Ukucubungula amathuluzi okuhlola. Eqinisweni, abantu abaningi bacabanga ukuthi ukuqedwa kokucutshungulwa kwengxenye kusho ukuthi umsebenzi usuphelile, futhi imali ingaqoqwa futhi ishiywe. Eqinisweni, leli iphutha elikhulu. Ingxenye ngayinye kanye nenqubo yokucubungula ngayinye idinga ukuhlonyiswa okuhambisanayo Ngale ndlela, ikhwalithi yokucubungula yezingxenye ingaqinisekiswa, futhi ukuhlolwa kwekhwalithi okuphelele kufanele kwenziwe ekugcineni. Ngokuhambisana nezidingo zokubekezelela usayizi nokuma kwezingxenye, izindinganiso zokuqina, njll., ukuhlolwa kwekhwalithi okuphelele kwezingxenye kungenziwa. Kuphela ngemva kwalezi zinqubo kungashiwo ukuthi ukucutshungulwa kwengxenye ngayinye kuqediwe. Kusukela ebusweni ukucela imali kumakhasimende, emabhizinisini amadala kahulumeni, ishabhu ngayinye izohlonyiswa ngesiteshi sokuhlola ikhwalithi njengesijwayelekile, futhi abasebenzi abahlola ikhwalithi banamazinga okuhlolwa kwekhwalithi yezinto zokusebenza.

Izisetshenziswa zamathuluzi nezinqubo zokusebenza zingamadokhumende ochwepheshe kakhulu futhi okuhlola ajwayelekile asetshenziswa njengesitifiketi sokusakazwa kwezingxenye. Unjiniyela wezinqubo ezinhle kufanele abe nokuqonda okujwayelekile kanye nokujwayela imininingwane yokuhlolwa kwekhwalithi yezingxenye, izinqubo kanye nokuhlolwa, ngale ndlela kuphela, Kungale ndlela kuphela singakwazi ukwakha ubuchwepheshe bokucubungula izingxenye futhi sikhiqize imikhiqizo efanelekile.

6. Lawula izindleko zokucubungula izingxenye. Noma yikuphi ukucubungula ngomshini okungabali izindleko kubizwa ngokuthi ama-hooligans. Lokhu kuziphatha kufana nokubulala izinkukhu nokuthola amaqanda. Akuyona into abantu abavamile abangayenza. Unjiniyela omuhle wokucubungula imishini akakwazi ukuphelela kuphela Ukuze aqedele ukucutshungulwa kwezingxenye ezihlukahlukene, angakwazi futhi ukunciphisa izindleko zayo yonke inqubo yokucubungula, ukuze kubhekwe njengokwenza umsebenzi kanjiniyela wokucubungula imishini. Noma yimuphi unjiniyela wezobuchwepheshe omangalisayo, inani elikhulu kunawo wonke ukucutshungulwa kwezingxenye Abantu abaningi bacabanga ukuthi ukulawulwa kwezindleko wukubamba ikhwalithi yokucubungula yezingxenye. Eqinisweni, emnothweni wemakethe yanamuhla, izindleko nekhwalithi sekuphenduke inkemba esika nhlangothi zombili emabhizinisini. Uma ungaqaphile, zombili izindwani zingalimaza abantu. Ikhwalithi yokucubungula okulawulwayo izindleko iyikhwalithi yokucubungula esebenzayo, ngaphandle kwalokho i-hooligan ngempela.

If you'd like to speak to a member of the Anebon team, please get in touch at info@anebon.com

Isikhathi sokuthumela: Feb-06-2021