Isofthiwe yanamuhla yokulingisa umshini wokulawula izinombolo we-CNC iqeda isidingo sokuqinisekisa ngesandla nokuhlola izingxenye kumjikelezo wokulingisa odla isikhathi wesitolo somshini, kodwa ingafinyelela ukusethwa okusheshayo nokunciphisa isikhathi sokuphumula. Ukulingisa nokutholwa kwamaphutha ohlelo kunqubo, ukungqubuzana okungaba khona phakathi kwezingxenye zamathuluzi omshini nezinye izindawo ezingasebenzi kahle (okuhlanganisa nesivinini esikahle sokusika) kungenziwa futhi kuhlolwe futhi kutholwe kusengaphambili.

Uma kubhekwa isimo esikhona ngo-2020, embonini egcwele izindaba ze-supply chain, ukushintshwa kwesidingo, ukugaya nokukhiqiza umsebenzi wokukhiqiza nezinye izinselelo, ukugcina inzuzo yokuncintisana kanye nesitolo semishini enenzuzo akuzinzile, kanye nokushoda kwabasebenzi/izikhala zamakhono.

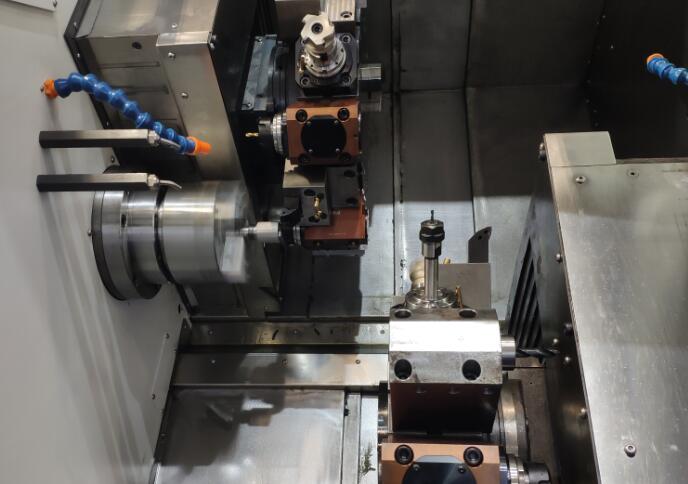

Futhi amaphutha ohlelo avamise ukuholela emiphumeleni engathi sína-kusuka ekulimaleni kwengxenye kuya ethuluzini elishaya isiqeshana sokusebenza, ukucekela phansi i-spindle ebizayo, futhi okubi nakakhulu, ukulimaza imishini ebizayo. Konke lokhu kuholela ekunciphiseni isikhathi esibizayo, ukubambezeleka kokukhiqiza kanye nokulahlekelwa kwemali engenayo. Ukusetshenziswa kwesofthiwe yokulingisa umshini we-CNC kuxazulula le nkinga futhi iyithuluzi elibalulekile labasebenza ngomshini ukuze baqinisekise ukuthi uhlelo lwe-CNC luhlelwe ngokunembile futhi ingxenye icutshungulwa ngendlela efanele okokuqala. Manje, inqubekelaphambili ekuthuthukisweni kwesofthiwe yenza kube nokwenzeka ukulingisa zonke izingxenye nokusebenza kwamathuluzi omshini we-CNC, futhi kuboniswe ngokuhlanganyela inqubo yokususa impahla yohlelo lwe-CNC. Ukuze uhlukanise ukusetshenziswa kwayo, u-opharetha womshini ufaka uhlelo olusebenzayo lwe-CNC, i-geometry yengxenye, ithuluzi elisetshenzisiwe, namanye amapharamitha asebenzayo, bese eluqhuba.

If you'd like to speak to a member of the Anebon team for custom precesion turned parts, please get in touch at info@anebon.com

Isikhathi sokuthumela: Nov-11-2020