Inqubo yokuthi ungamodela kanjani ngamafayela ezithombe ze-2D. Okulandelayo yi-2D:

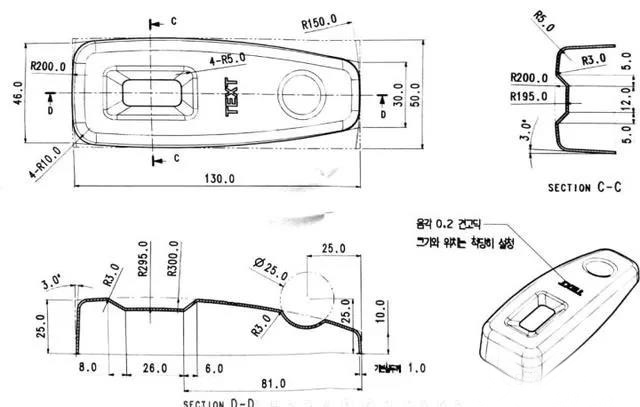

Okokuqala, ngabona i-2D enjalo. Uma ngifuna ukumodela, ngiqale ngihlaziye futhi ngicacise ukucabanga kwami. Ngokusho kwenhlangano, ngiyakwazi ukubona cishe izinhlangothi eziyisithupha, phezulu naphansi, kwesokunxele nakwesokudla, ngaphambili nangemuva.

1. Ngezansi-indiza.

2. Indawo engaphezulu egobile: indawo engaphezulu idinga ukudwetshwa ngokuhlukana, futhi izithiyo ezihlobene ngokuyinhloko zenziwa nge-sectionC-C ne-sectionD-D.

3. Kwesobunxele, kwesokudla, ngaphambili nangemuva: Kukhona okusalungiswa endizeni. Kulokhu, i-extrude+draft ngokuvamile isetshenziselwa ukudweba. Ungakwazi futhi ukudweba ijika elihambisanayo bese udweba ngomyalo ohambisanayo wendawo, kodwa inqubo inzima.

Ngemva kokunqunywa komqondo wesithombe esijwayelekile, bheka imininingwane, ikakhulukazi isikwele nesiyingi sesithombe, esingaphazamisi isithombe esiphelele, dweba ngokwehlukana, futhi umqondo usuqediwe.

Okulandelayo ukukhishwa okuqediwe, sicela ubhekisele ku:

Amathiphu:

1. Qondisa ukukhethwa kwendawo yesistimu: ngokuvamile khetha indawo lapho iphoyinti lokuqala lobukhulu liyisikhungo esikhulu kunazo zonke noma isikhungo se-symmetrical yesibalo esilinganayo. Uma ubheka isithombe, ukuphambana kwe-sectionC-C ne-DD kungcono kakhulu.

2. Ijika elisizayo esilisebenzisayo lapho sidweba izithombe kufanele liguqulwe libe imigqa eyinsiza (imigqa edayishiwe) ngokuhamba kwesikhathi, okubaluleke kakhulu emidwebeni eyinkimbinkimbi.

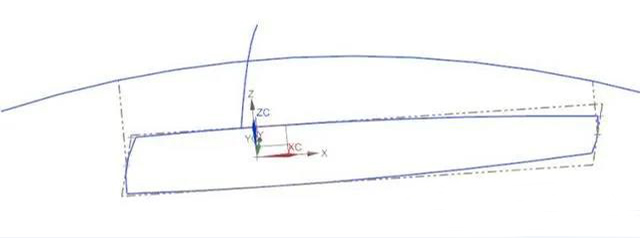

Qondisa imvelaphi: phezulu naphansi kuyahambisana, kwesokunxele nakwesokudla ngokwesigaba DD P7 =81+26/2.

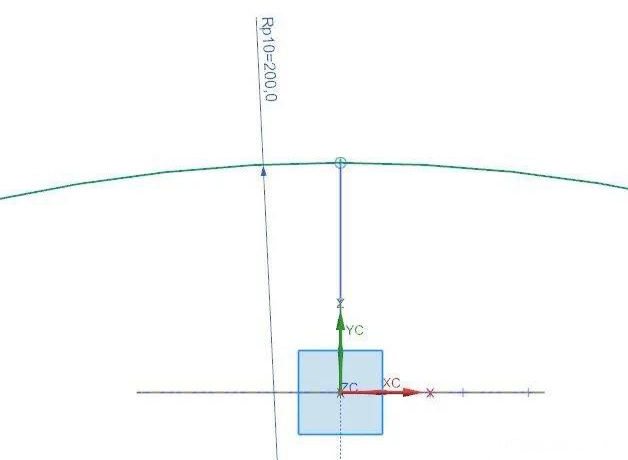

Isithombe somdwebo endaweni engezansi siqedile.

Amathiphu:

1. I-symmetry ephezulu naphansi:

Isibuko se-arc esiphezulu siyehla

Isikhungo sama-arcs amabili kwesokunxele nakwesokudla siku-XC

2. Lapho uphungula ijika, qaphela ngokukhethekile ukuthi ikhona yini imigqa emifushane esele emakhoneni.

3. Uma iphuzu lokuvinjelwa likumugqa oqondile, umkhuba ongcono ukukhetha umugqa oqondile kuqala, bese kuyashesha ukukhetha iphuzu.

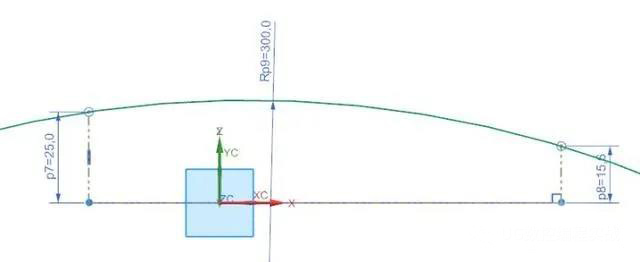

Ingxenye

Ukukhiqizwa kwe-DD, ngoba ngemva kokukhethwa kwesistimu yethu yokuhlanganisa, Isigaba DD singakhetha ngokuqondile indiza ye-XZ

Amathiphu:

Lapho wenza indawo efanele, ijika elidwetshiwe ngokuvamile lide kancane kunosayizi, futhi indawo eyenziwe kamuva izoba nkulu kancane, elungele ukuhlanganisa nokukhipha okuhambisanayo. Ngaphandle kwezingqinamba zosayizi.

Ingxenye

Ukukhiqizwa kwe-CC, ngoba ngemva kokukhethwa kwesistimu yethu yokuxhumanisa, Isigaba CC singakhetha ngokuqondile indiza ye-YZ.

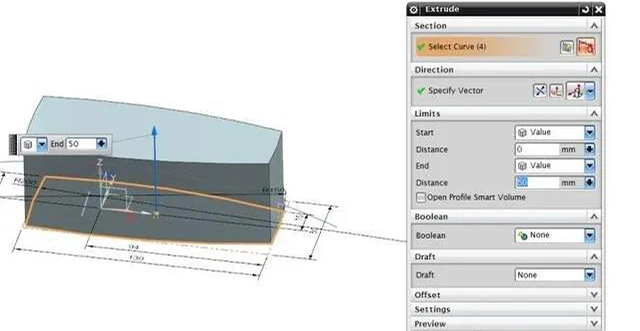

Nweba okuqinile komzimba wethu oyinhloko.

Amathiphu:

Ubude be-Extrude kufanele bube bukhulu kunephuzu eliphakeme kakhulu lomkhiqizo ngangokunokwenzeka (ubukhulu obuphakeme buphawulwe ngokuthi 25, futhi ubude lapha bungama-50), ukuze kube lula ukuhlanganisa nokukhipha okuhambisanayo. Ngaphandle kwezingqinamba zosayizi.

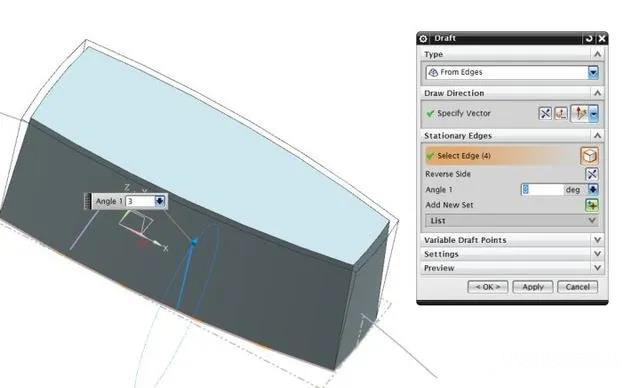

Hlela i-engeli yombuzo.

Ijika eliwumkhawulo elingaphezulu lidwetshiwe

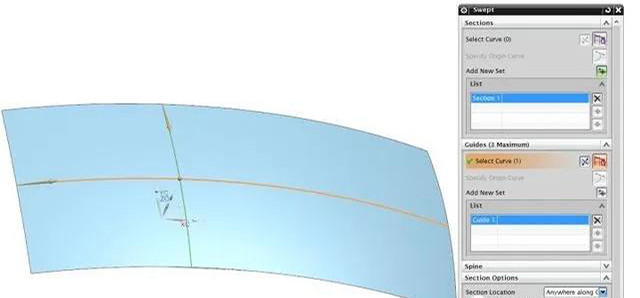

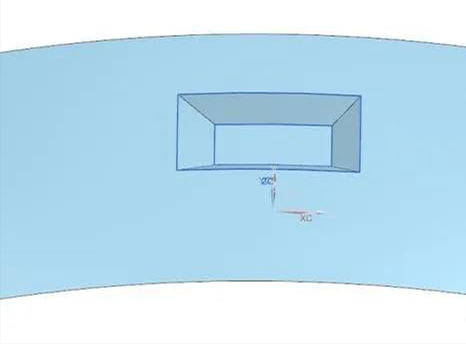

Ukukhiqizwa kwendawo ephezulu: sebenzisa umyalo wokushanela.

Amathiphu:

Ebhokisini lomyalo ngakwesokudla, hlola ukwakheka kwe-Londoloza ngangokunokwenzeka, ukuze ubuso obukhiqizwayo buhambisane kakhulu nezingqinamba zejika esilidwebile.

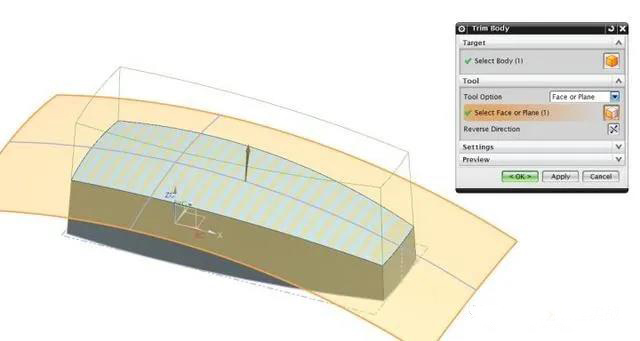

Sika umzimba wethu oyinhloko ngobuso esiwushanele ukuze siqedele isithombe esiyisisekelo sendawo engaphezulu.

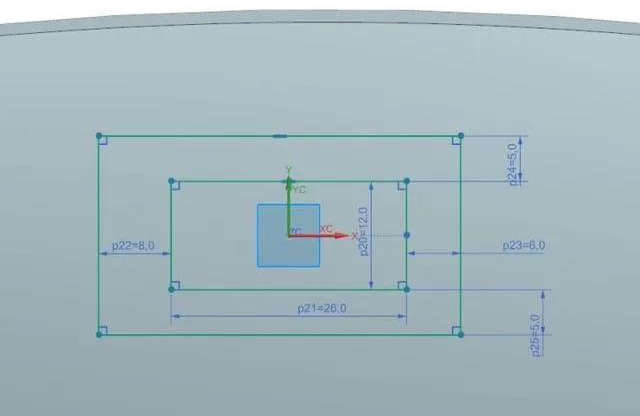

Dweba isithombe esinemininingwane yesikwele ohlangothini lwesobunxele lomkhiqizo. NgokweSigaba CC kanye nesigaba DD, isithombe sesikwele esivezwe endaweni engezansi singavinjelwa. Isithombe esingenhla siwumdwebo odwetshwe endizeni ye-XY.

Isigaba CC usayizi R200, R195 kanye nesigaba DD

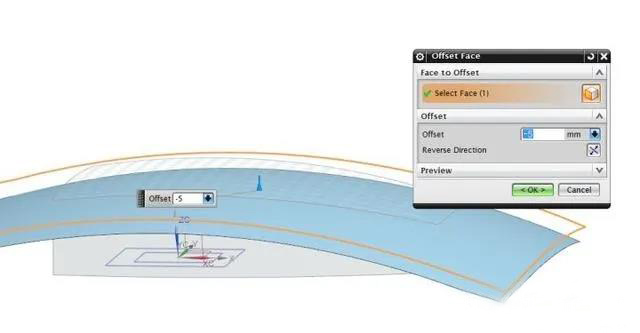

Ngo-R300, u-R295, sisebenzisa i-offset-5 endaweni engaphezulu ukuze siqedele ingaphezulu ngo-R omncane, futhi umphumela ophelile unjengoba kukhonjisiwe emfanekisweni ongezansi.

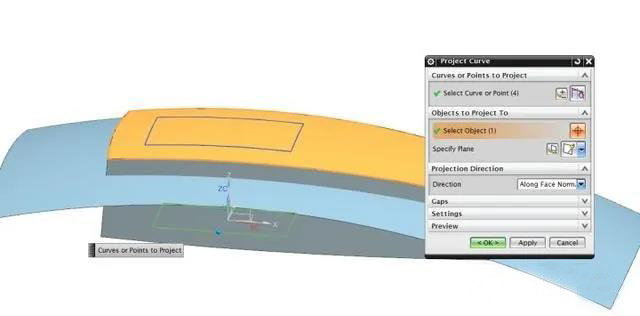

Faka unxande omkhulu osanda kudwetshwa endaweni engezansi phezu kuka-R300.

Dala unxande omncane osanda kudwetshwa endaweni engezansi phezu kuka-R295.

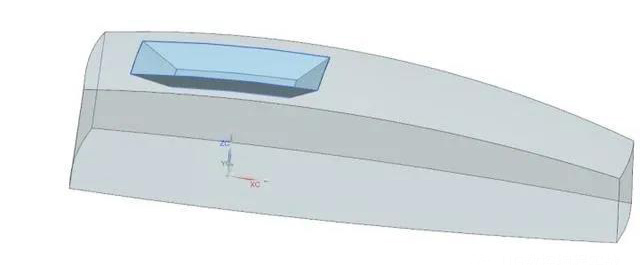

Isithombe sokuqina ngemva kokufihla umzimba oyinhloko siboniswa emfanekisweni.

Ngokusebenzisa

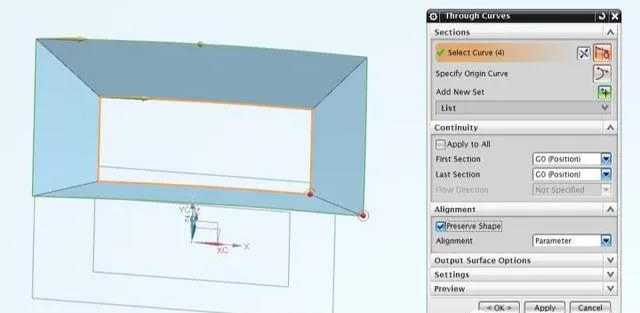

Ijika lidweba amathambeka amane emfanekisweni ongenhla.

Amathiphu:

1. Qaphela ukuthi indawo yokuqala kanye nesiqondiso sonxande abangaphezulu nabaphansi kufanele kufane, ngaphandle kwalokho ihluzo zizohlanekezelwa.

2. Londoloza ukwakheka kufanele kukhethwe, ngaphandle kwalokho ngeke kube khona ingxenye phakathi kwabo bonke ubuso obubili, ukuguquka okubushelelezi, futhi ayikho indlela yokudonsa.

Hlola Londoloza umumo kwesokunxele, bese ususa ukumaka Londoloza kwesokudla

shape, sicela unake umehluko ekhoneni.

Bonisa indawo ebangeni layo le-offset lalingu-5 ngaphambili.

Ngemva kokunquma ubuso bezingxenye ezine ezisanda kwakhiwa, njengoba kuboniswe emfanekisweni ongenhla.

Ngemuva kokuthunga izindiza ezimbili, shintsha yonke indawo.

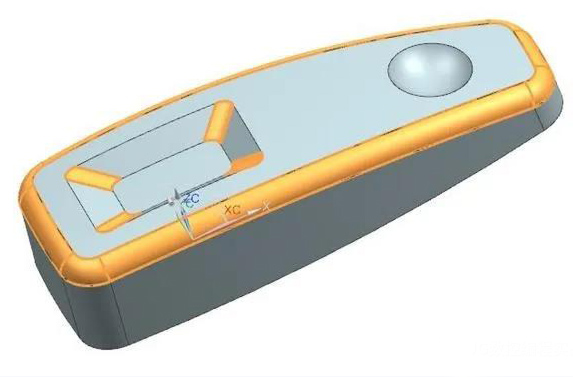

Ibonisa umzimba oqinile womkhiqizo, ungabona isithombe sonke njengoba kukhonjisiwe ngenhla

Namathisela yonke indawo ngemuva kokuthunga emzimbeni omkhulu.

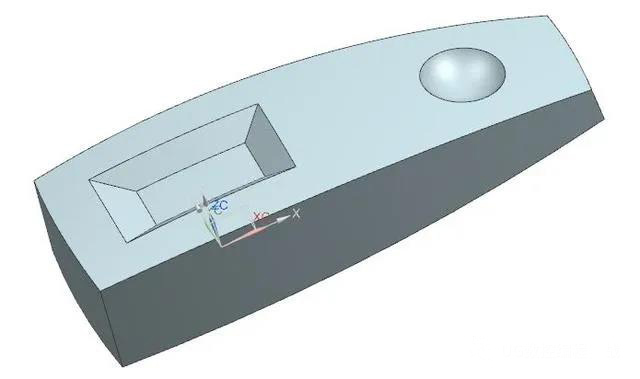

Dweba isikhungo se-sphere ngakwesokudla bese ufaka iphoyinti.

Khetha iphuzu esiliphawule ngosayizi bese udweba i-sphere.

Yenza ukukhipha kwe-Boolean emzimbeni naku-sphere.

Thola isithombe sethu sisonke, i-chamfering negobolondo kuphela.

Amathiphu:

1. Ukukhetha ukuhleleka kwe-chamfering negobolondo: Bona ukuthi iyiphi irediyasi ye-chamfer nokuqina kodonga lwegobolondo olukhulu, yenza enkulu kuqala. Kulo mfanekiso, chamfer amakhona kancane, futhi chamfer kuqala.

2. Ama-chamfer amaningi anama-radii ahlukene, adwetshwe ngokulandelana ukusuka kokukhulu kuye kwabancane

Qaphela ukuthi lapho ukhetha umngcele wengxenye, isiqondiso sohlangothi lwempahla ngokuyinhloko sincike ekutheni into esele ingaphandle noma ingaphakathi kwejika.

If you'd like to speak to a member of the Anebon team, please get in touch at info@anebon.com

Isikhathi sokuthumela: Mar-10-2021