1. Umsebenzi owenziweyo

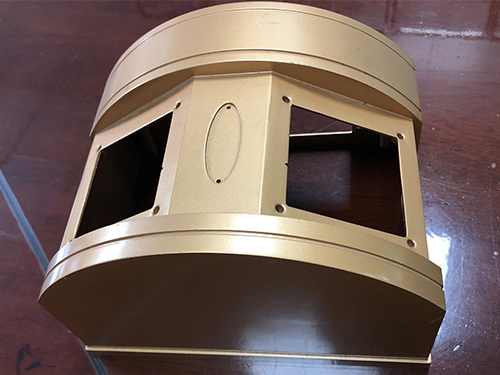

1. Umphandle wangaphandle ufuneka ukuba uqaqambe kwaye ube mcaba. Imingxunya emibini ye-punch yongezwa kwifreyimu yokungunda yangaphambili nasemva. Nika ingqalelo kwiindawo apho kungekho zifakelo zokuthintela iindawo ukuba zingawi.

2. Isakhelo sokubumba ipleyiti ye-AB sihambelana nomnye ukwenza i-0.1-0.15, kunye ne-flying water baffle yongezwa ukukhusela i-aluminium ukuba iphume kwaye ibangele abantu.

3. Ukuze uthintele i-template ukuba ingatshintshi, ubuncinane yenza iikholamu ezimbini zokuxhasa, enye kwi-shunt cone, kunye ne-shunt cone. Qaphela ukuba ungaphazamisani namanye amalungu.

4. I-mold yongeza i-2-4 i-brackets ephakathi kunye ne-middle brackets, kwaye i-middle bracket side yenziwe kakuhle kunye nomda.

5. I-plate ephantsi ye-mold kufuneka ivule ukuququzelela ukutshatyalaliswa kobushushu.

6. Iimbombo ezine zobumba kufuneka zinqunywe ukuze zithintele ekubetheni iposti eluhlaza ngexesha lofakelo.

7. Itheyibhile yangaphakathi yomngxuma wendandatho yokumisa iyadingeka ukuba ifakwe i-nitrided emva kokusila kwangaphakathi kunye nokupholisa kunye nolwalathiso lwe-ejection.

8. Ubude obuvela ngaphantsi kwendandatho yokupholisa phezu kwendawo yokubeka indawo ukuya kumphezulu we-cone ye-splitter ngokuqhelekileyo ilingana nobukhulu bekhekhe. Kukho iindlela ezimbini zokulungisa le ntsimbi yokupholisa: i-welding kunye nokufudumeza kunye nokucinezela.

9. I-shunt cone kufuneka ipholiswe ngokuthuthwa kwamanzi, kunye ne-25-30mm kude nomphezulu we-shunt cone.

10. Imingxuma emine yeposi yesikhokelo yesiseko sokubumba kufuneka ibe yi-prying grooves enobunzulu be-8-10mm.

11. Isiseko sokubumba kufuneka sicinywe kwaye siphephe, ngokukhethekileyo isiseko sokubumba esibunjiweyo.

12. Ukuze kuququzelelwe ukukhutshwa kwezinto ezifakwe kwi-mold yangaphakathi, umngxuma unokongezwa phezu kwendawo yokubumba, kwaye emva koko i-screws ezimbalwa ezingenantloko zingaqokelelwa, ukwenzela ukuba kube lula ukuqhaqha kunye nokubuyisela ukufakwa.

13. Imingxuma yokuxhoma kufuneka ibe yi-M30 ubuncinane kunye ne-45 ubunzulu, kwaye ubuncinane ibe yi-2 phezulu.

14. I-slingshot yangaphandle kufuneka ixhotyiswe ngesigqubuthelo sokukhusela entwasahlobo ukukhusela intwasahlobo ukuba ingakhuli.

15. Umphezulu ophezulu kunomgangatho wesiseko sokubumba kwaye kufuneka udibanise nomhlaba kufuneka wongezwe kunye neentsika zokuxhasa.

2. Ukubumba kwangaphakathi, faka

1. Yenza unyango lokunciphisa uxinzelelo ngaphambi kokuba unyango lobushushu emva kokulungiswa. Ukucima ialluminiyam ngokubanzi HRC45+/-1°C, ingxubevange yezinc ecima HRC46+/-1-1°C

2. Ukunyamezela okufanelekileyo kwe-mold yangaphakathi: Ngokuqhelekileyo, kufuneka ibe malunga ne-0.05-0.08mm encinci kunesakhelo sokubumba, kwaye inokukhutshwa ngokulula kwaye ifakwe kwisakhelo sokubumba kunye neringi yokuphakamisa.

Unyamezelo lwethimble: ukucocwa kwethanga elikhulu kuno okanye elilingana ne-8mm yi-0.05mm,

Umsantsa wethanga ongaphantsi okanye olingana ne-6mm yi-0.025mm.

3. Zonke ii-engile ezichanekileyo nezibukhali kumngundo wangaphakathi kufuneka zibe ngaphezulu kwe-R0.5mm.

4. Sebenzisa izikhonkwane ezisicaba ukuvala imingxuma engaphezulu kumphezulu wemold yangaphakathi.

3. Umgijimi kunye noyilo lwenkqubo yokukhupha i-slag

1. Indlela ehamba phambili yekeyiki yelaphu kwi-shunt cone kufuneka ibe ngaphakathi kwe-1/3 yendawo yobuso besangqa. Ngale ndlela, indawo yokuhlukana ivaliwe ngaphambi kokuba izinto ezibandayo zingene ngokukhawuleza kwi-cavity.

2. Umjelo oyintloko ngaphezu kwe-cone yokwahlula kufuneka yenziwe "W" imilo, kwaye ubukhulu bekhekhe kufuneka bube yi-15-20mm.

3. Ngokuqhelekileyo, ubude bomgijimi oyintloko kufuneka bube yi-30-35mm, kwaye isikhunta kufuneka sibe ngu-5-10 ° kwelinye icala.

4. Ngokuqhelekileyo, umzila we-cross flow ulungele ukugoba kwaye wenze amanyathelo angaphezu kwama-2 ukukhusela izinto ezibandayo ekungeneni kwi-cavity ngokusebenzisa i-channel flow flow, okubangelwa imigca yokuthintela ebandayo ebusweni bemveliso.

5. Ngokuqhelekileyo, kulungele ukongeza i-2 buffers kwindawo yesango apho i-channel flow flow ingena kwimveliso, ukwenzela ukuba izinto ezibandayo zivaliwe ngokupheleleyo ngaphandle kwendawo.

6 Ngokuqhelekileyo, inqanaba le-thimble phantsi komgijimi oyintloko kufuneka libunjwe, kwaye kufuneka libe ngaphezu kwe-R2.

7. Ingundoqo ephumayo kwicala elichasene nomgijimi oyintloko kufuneka igwenywe, kwaye isikhwama se-slag kwicala elichasene nomgijimi oyintloko kufuneka sibe yinkunkuma kuqala, kwaye emva koko uvule ngokwemeko.

8. Isikhwama se-slag sikulungele ukusebenzisa i-plane yenkundla, i-cross-sectional shape of a semicircle, kunye ne-inlet yamanzi kunye ne-groove exhaust ihlukaniswe yi-1/3. I-inlet yamanzi ye-slag bag nayo kufuneka igqitywe.

9. I-exhaust slot kufuneka ithotywe kwaye iguqulwe ngokufanelekileyo, ngokulandela imigaqo ye-"3.2.1".

10. Ukuze kuququzelelwe ukucutshungulwa, isango ekudibaneni komzila ohamba ngokuthe ngqo kunye nemveliso kufuneka igqitywe, kwaye akulula ukulahlekelwa yinyama ngexesha lokucubungula.

4. Indlela yokutsala engundoqo

1. Isilayidi kufuneka senziwe ubuncinane umngxuma wokufa ojingayo kwindawo ephezulu nangaphantsi ukuququzelela ukuchithwa kunye nokudibanisa.

2. I-bottom of the slider kufuneka ibe yindawo yokusika, kwaye i-strip-resistant strip kufuneka yenziwe ibe yizicucu ezi-2 ze-8-12mm phezulu kunomgangatho ophantsi we-mold mold ukuququzelela ukucocwa kwe-aluminium slag ngexesha lokuvelisa.

3. I-bead yesilayidi kufuneka ibe yi-groove engagugiyo, eyi-45 ° kunye necala lokutsala.

4. Umatshini wokutyibilika kufuneka uguquguquke ekukhokeleni nakwi-sliding, uzinzile ekuhambeni, kunye nokukhutshwa kwe-0.08--0.12MM.

5. Emva kokuba i-mold ivaliwe, i-slider kunye nebhloko yokukhiya kufuneka igxininiswe ngokuqinileyo, indawo yoqhagamshelwano ayikho ngaphantsi kweyesibini kwisithathu, kwaye ine-prestress ethile.

If you'd like to speak to a member of the Anebon team for Aluminum Casting,CNC Machined Custom Service,CNC Turning Alloy, please get in touch at info@anebon.com

Ixesha lokuposa: Feb-25-2021