Inkqubo yendlela yokwenza imodeli ngeefayile zemizobo ye-2D. Oku kulandelayo yi-2D:

Okokuqala, ndabona i-2D enjalo. Ukuba ndifuna ukwenza imodeli, ndiqale ndihlalutye kwaye ndicacise ukucinga kwam. Ngokwequmrhu, ndibona malunga namacala amathandathu, phezulu nasezantsi, ekhohlo nasekunene, ngaphambili nangasemva.

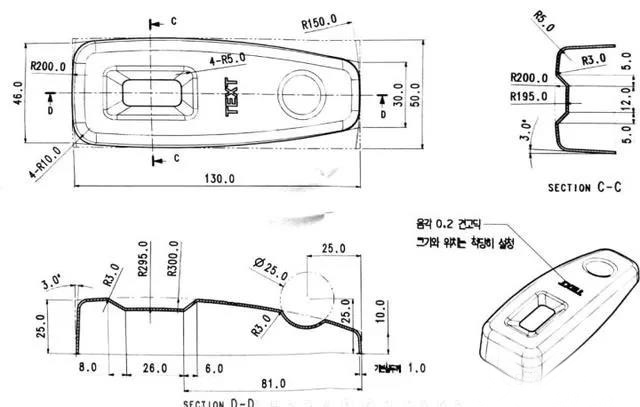

1. Ngezantsi-inqwelomoya.

2. Umphezulu ogobileyo ongaphezulu: umphezulu kufuneka utsalwe ngokwahlukileyo, kwaye izithintelo ezihambelanayo ziqhutyelwa ikakhulu ngecandelo leC-C kunye necandelo le-D-D.

3. Ekhohlo, ekunene, ngaphambili nangasemva-inqwelomoya: Kukho idrafti kwinqwelomoya. Kule meko, i-extrude+draft isetyenziswa ngokubanzi ukuzoba. Unako kwakhona ukuzoba ijika elihambelanayo kwaye uzobe ngomyalelo womphezulu ohambelanayo, kodwa inkqubo inzima.

Emva kokuba ingcamango yomfanekiso jikelele inqunywe, jonga kwiinkcukacha, ngokukodwa isikwere kunye nomfanekiso wesangqa, ongachaphazeli umfanekiso opheleleyo, udwebe ngokwahlukileyo, kwaye ingcamango igqityiwe.

Oku kulandelayo lunikezelo olugqityiweyo, nceda ubhekisele ku:

Iingcebiso:

1. Ulungelelaniso lokukhetha indawo yenkqubo: ngokuqhelekileyo khetha indawo apho isiqalo somlinganiselo sisona sininzi okanye iziko le-symmetrical figure ye-symmetrical figure. Ukuba ujonga umfanekiso, ukuhlangana kwecandelo C-C kunye neDD yeyona nto ingcono.

2. Igophe elincedisayo esilisebenzisayo xa sizoba imifanekiso kufuneka iguqulwe ibe yimigca encedisayo (imigca edawuniweyo) ngexesha, nto leyo ebaluleke kakhulu kwimizobo entsonkothileyo.

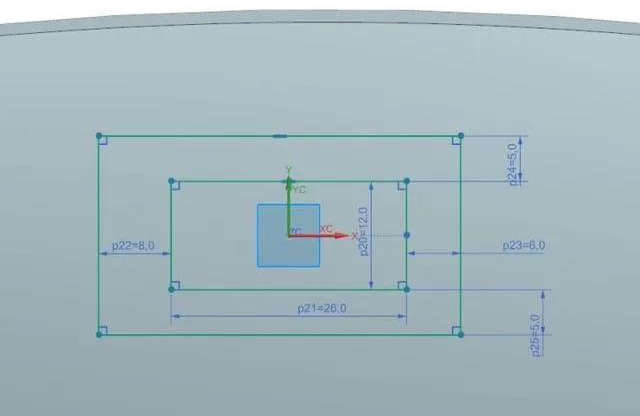

Ulungelelaniso lwemvelaphi: phezulu nasezantsi symmetrical, ekhohlo nasekunene ngokwecandelo DD P7 =81+26/2.

Umfanekiso womzobo kumphezulu ongezantsi ugqityiwe.

Iingcebiso:

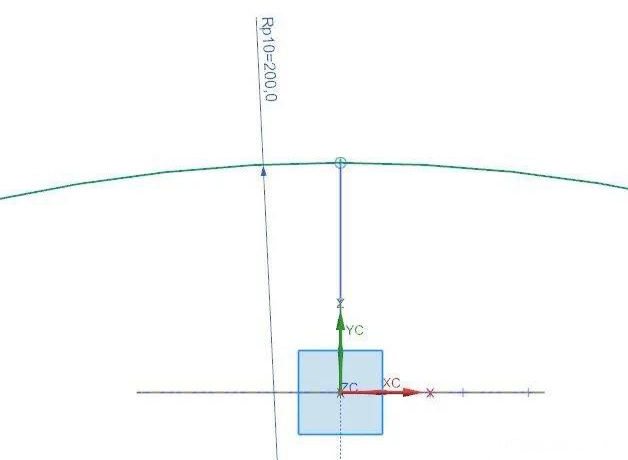

1. I-symmetry ephezulu nasezantsi:

Isibuko esiphezulu se-arc siyehla

Umbindi wee-arcs ezimbini ngasekhohlo nasekunene useXC

2. Xa ucheba ijika, nikela ingqalelo ekhethekileyo ukuba ngaba kukho imigca emifutshane eseleyo ezikoneni.

3. Xa indawo yomnyanzelo isendleleni ethe tye, umkhwa ongcono kukukhetha umgca othe ngqo kuqala, kwaye ngokukhawuleza ukhethe inqaku.

Icandelo

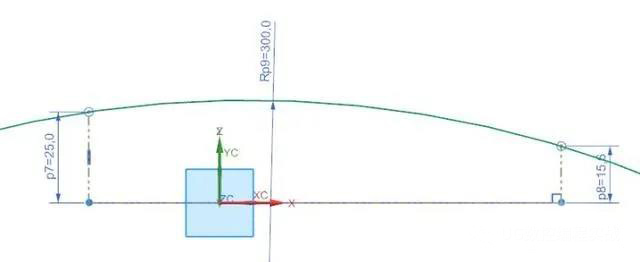

Ukuveliswa kweDD, kuba emva kokuba inkqubo yethu yokulungelelanisa ikhethiwe, iCandelo leDD linokukhetha ngokuthe ngqo indiza ye-XZ

Iingcebiso:

Xa usenza umgangatho ochanekileyo, ijika elizotyiweyo ngokuqhelekileyo lide kancinane kunobukhulu, kwaye umgangatho owenziwe kamva uya kuba mkhulu, olungele ukongezwa okuhambelanayo kunye nokuthabatha. Ngaphandle kwemiqobo yobungakanani.

Icandelo

Ukuveliswa kweCC, kuba emva kokuba inkqubo yethu yokulungelelanisa ikhethiwe, iCandelo leCC linokukhetha ngokuthe ngqo indiza ye-YZ.

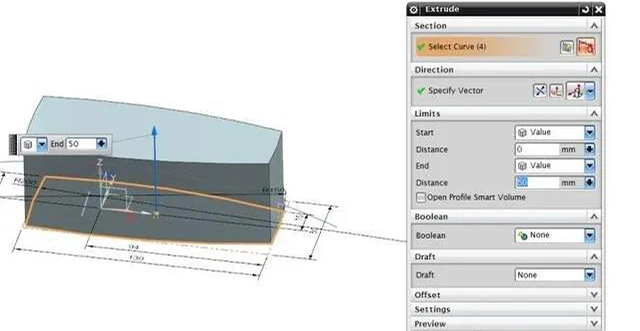

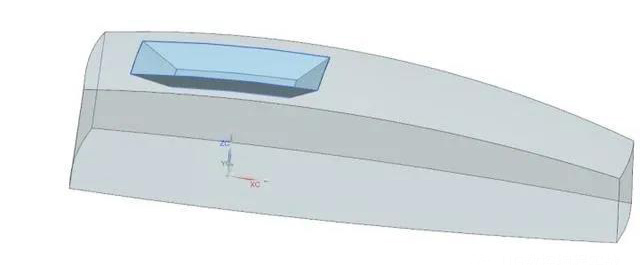

Yandisa okuqinileyo kumzimba wethu ophambili.

Iingcebiso:

Ukuphakama kwe-Extrude kufuneka kube kukhulu kuneyona ndawo iphakamileyo yemveliso kangangoko kunokwenzeka (umlinganiselo ophezulu uphawulwe njenge-25, kunye nokuphakama apha ngama-50), ukwenzela ukuba kuququzelele ukudibanisa okuhambelanayo kunye nokusebenza kokuthabatha. Ngaphandle kwemiqobo yobungakanani.

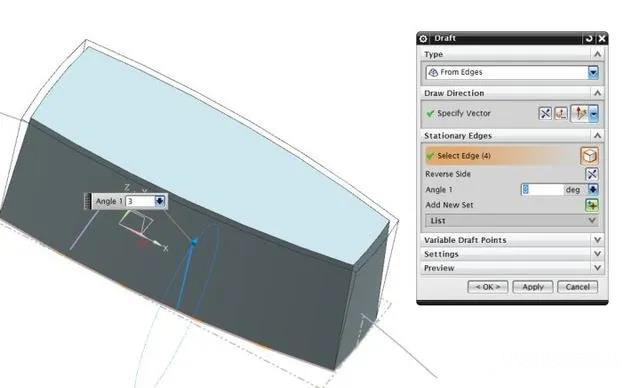

Drafta i-engile yombuzo.

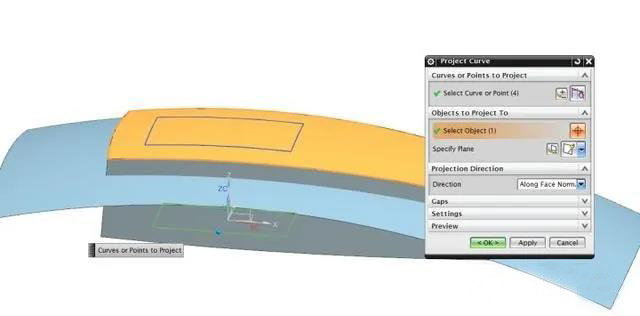

Ijika lokunyathela kumphezulu ophezulu lizotyiwe

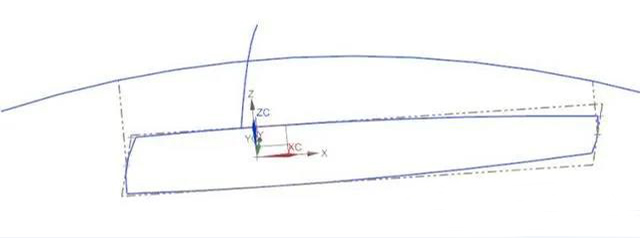

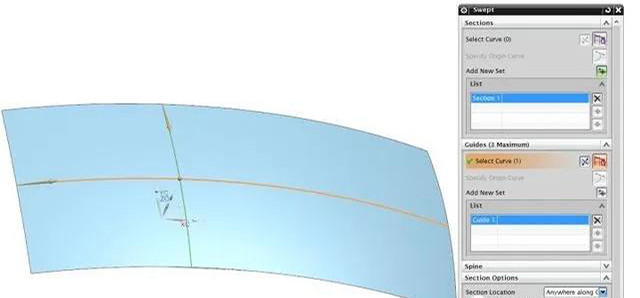

Imveliso yomphezulu ophezulu: sebenzisa umyalelo itshayelwe.

Iingcebiso:

Kwibhokisi yomyalelo ngakwesokudla, khangela i-Gcina imilo kangangoko kunokwenzeka, ukwenzela ukuba umphezulu oveliswayo uhambelana ngakumbi nemiqobo ye-curve esiyizobileyo.

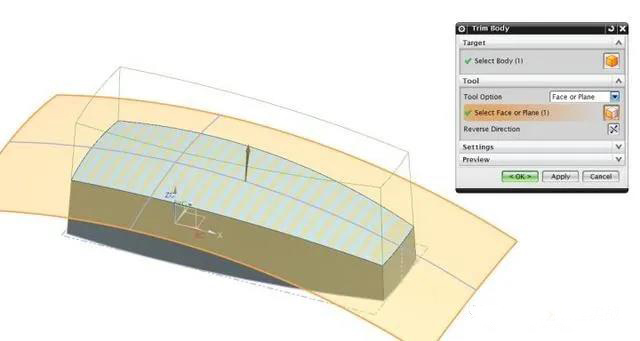

Sika umzimba wethu ophambili ngomphezulu esiwutshayeleyo ukuze sigqibezele umfanekiso osisiseko womphezulu ongaphezulu.

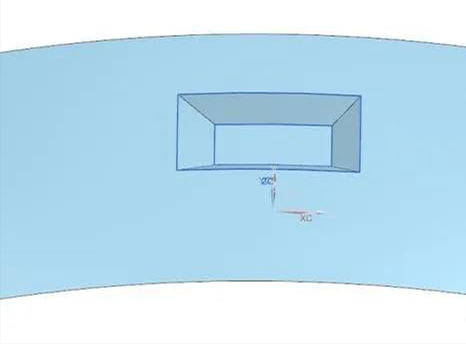

Zoba umfanekiso ocacileyo wesikwere kwicala lasekhohlo lemveliso. Ngokutsho kweCandelo leCC kunye necandelo le-DD, umfanekiso wesikwere ocetywayo kumphezulu ophantsi unokunyanzeliswa. Umfanekiso ongasentla ngumzobo ozotywe kwinqwelomoya ye-XY.

Icandelo leCC ubukhulu be-R200, i-R195 kunye necandelo DD

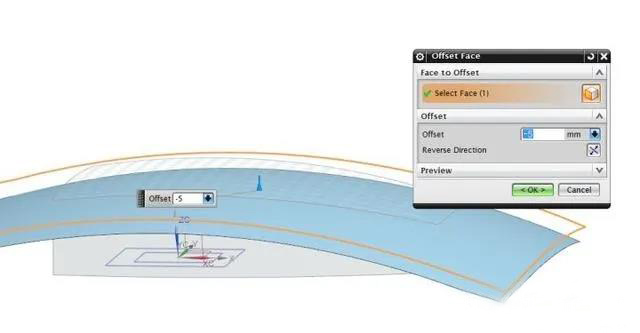

Nge-R300, i-R295, sisebenzisa i-offset-5 kumphezulu ongaphezulu ukugqiba umphezulu nge-R encinci, kwaye umphumo ogqityiweyo uboniswe kumfanekiso ongezantsi.

Yenza uxande olukhulu olusanda kuzotywa kumphezulu ongezantsi kumphezulu we-R300.

Cela uxande oluncinane olusanda kuzotywa kumphezulu ongezantsi kumphezulu wama-R295.

Umfanekiso oqinileyo emva kokufihla umzimba oyintloko uboniswa kumzobo.

Ngokusebenzisa

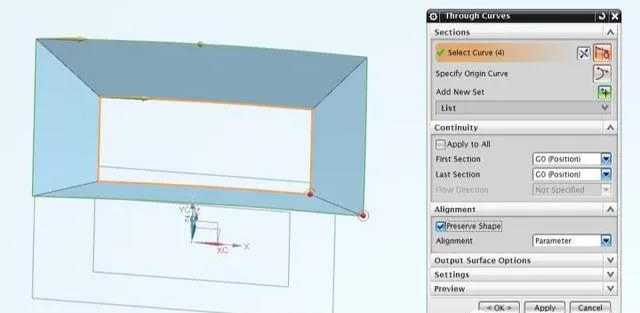

Igophe lizoba amathambeka amane kulo mfanekiso ungentla.

Iingcebiso:

1. Qaphela ukuba indawo yokuqala kunye nesalathiso soxande oluphezulu nasezantsi kufuneka lufane, kungenjalo imizobo iya kuphazamiseka.

2. Gcina imilo kufuneka ikhethwe, kungenjalo akuyi kubakho nxalenye phakathi kobuso obubini, inguqu egudileyo, kwaye akukho ndlela yokugubungela.

Jonga Gcina imilo ekhohlo, kwaye ungaqwalasela Gcina ekunene

imilo, nceda unikele ingqalelo kumahluko ekoneni.

Bonisa umphezulu onomgama wokulinganisa wawungu -5 ngaphambili.

Emva kokucheba ubuso bamacandelo amane asanda kwenziwa, njengoko kubonisiwe kulo mfanekiso ungentla.

Emva kokuthunga iindiza ezimbini, tshintsha yonke indawo.

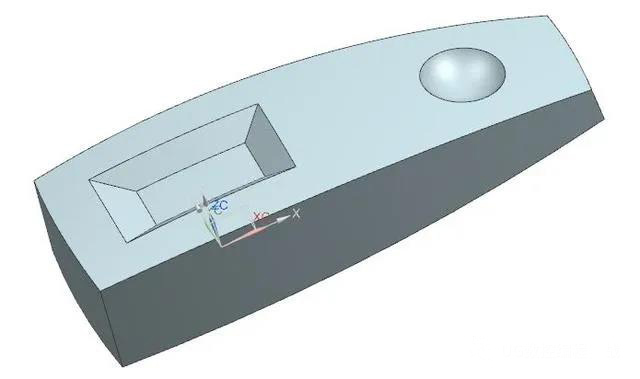

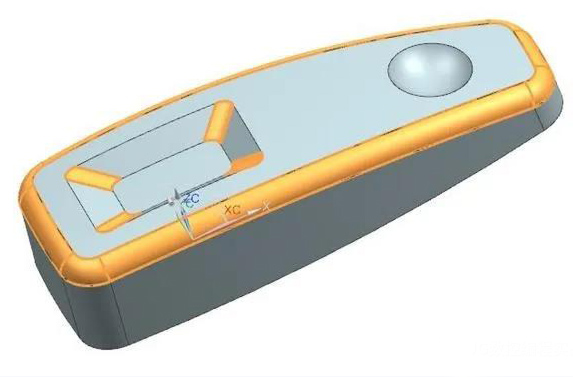

Ibonisa umzimba oqinileyo wemveliso, unokubona umfanekiso opheleleyo njengoko kuboniswe ngasentla

Pakisha yonke indawo emva kokuthunga ukuya kumzimba oyintloko.

Zoba umbindi wengqukuva ngasekunene uze ufake inqaku.

Khetha inqaku esiliphawulileyo ngobungakanani kwaye uzobe i-sphere.

Yenza ukuthabatha kweBoolean kumzimba kunye nesphere.

Fumana umfanekiso wethu uwonke, kuphela i-chamfering kunye neqokobhe.

Iingcebiso:

1. Ukukhetha ulandelelwano lwe-chamfering kunye neqokobhe: Jonga ukuba yeyiphi i-chamfer radius kunye nobukhulu bodonga lweqokobhe elikhulu, yenza enkulu kuqala. Kulo mzobo, chamfer iikona kancinane, kwaye chamfer kuqala.

2. Ii-chamfers ezininzi ezinerediya ezahlukeneyo, ezotywe ngokulandelelana ukusuka kwinkulu ukuya kwencinci

Qaphela ukuba xa ukhetha umda wenxalenye, ulwalathiso lwecala lezinto eziphathekayo luxhomekeke ekubeni izinto eziseleyo zingaphandle okanye ngaphakathi kwijika.

If you'd like to speak to a member of the Anebon team, please get in touch at info@anebon.com

Ixesha lokuposa: Mar-10-2021