Likarolo tsa ho Lahlela ka Auto Die

Mokhoa oa Tlhahiso:

1.Hlahloba moralo oa karolo, litšoantšo le maemo a boleng ho tsoa ho bareki.

2. Mold le Tooling moralo & tlhahiso

3. Teko ea hlobo le Tooling & netefatsa sampole

4. Shoa ho lahlela li-castings tse tala

5.Kalafo ea holim'a sefahleho: Ho fokotsa, ho tlosa, ho bentsa, ho hloekisa, ho hloekisa, passivation & ho roala matla le litlhoko tse ling tse tsoang ho Moreki.

6. Precision machining: CNC lathes, ho sila, ho cheka, ho sila joalo-joalo

7. Tlhahlobo e Felletseng

8. Ho paka

9. Phano

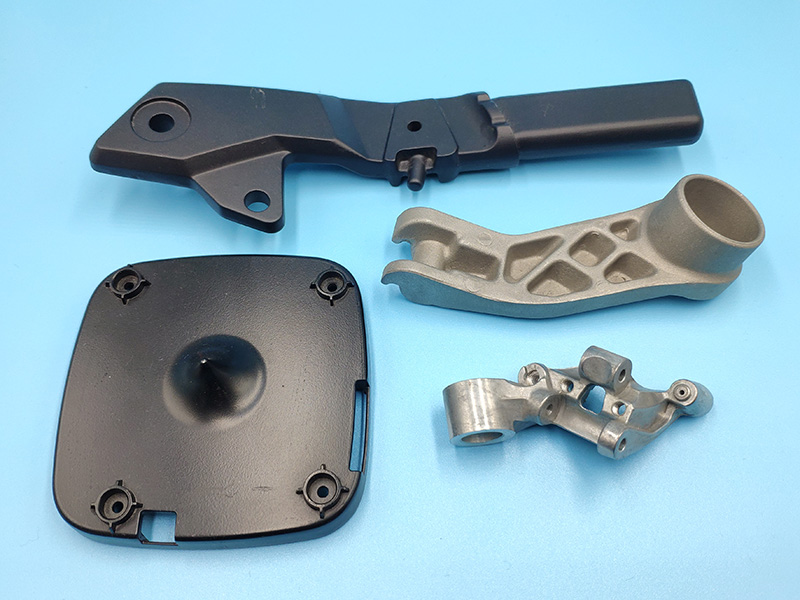

| Technics & process | Aluminium alloy die casting: 44300,44300/46000/ADC12/A360/A380/Alsi9cu3, joalo-joalo. Aluminium alloy profil extrusion: 6061 6063 CNC machining le Phetoho: 6061 6063 Karolo ea Boima: Ho tloha ho 10g ho isa ho 15000g Moetso oa hlobo: Setšoantšo sa moralo oa karolo (prt/fem/igs/stp/dxf/model/xt/xb forms)ho fana ka hlobo |

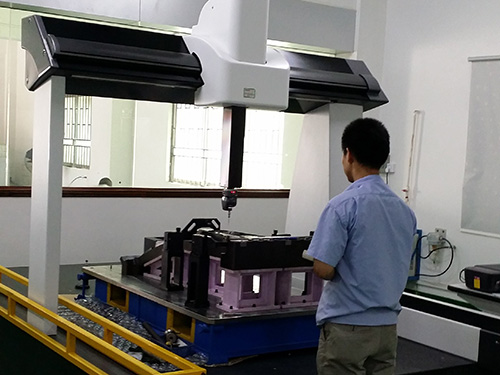

| Thepa | Mochini oa ho lahla oa kamore e batang: 200T/280T/400T/500T/800T/1250T.CNC litsi,CNC turning, CNC lathes, pulse ea motlakase, ho seha mohala, ho sila, ho cheka, ho sila |

| Kalafo ea Bokaholimo | Ho fokotsa, ho phunya, ho pentša, ho qhomisa lithunya, ho qhomisa lehlabathe, ho oela, ho roala phofo,anodizing, chrome, zinki, electrophoresis, passivation, ho roala lik'hemik'hale |

| Thuso ea Software | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Kopo ea Lihlahisoa | Koloi Baesekele le sethuthuthu Monyako le lifensetere le thepa ea ka tlung Sesebelisoa sa lapeng Metara ea khase Sesebelisoa sa matla |

Tšebeletso:

1. OEM le ODM.

2. Qotsulo nakong ea lihora tse 24.

3. Ts'ebeletso ea tlhahlobo ea SGS kapa tlhahlobo efe kapa efe e fanoeng ke Moreki.

4. Tšebeletso ea ho romela thepa.

5. Kamora tshebeletso

Hobaneng re khetha:

1.Sehlopha sa rona sa tsebo ea botekgeniki le ba nang le boiphihlelo se netefatsa hore re khona ho fana ka ts'ebeletso ka maemo a Machabeng ho bareki ba rona.

2.Rely on International tooling meralo mohopolo le tlhahiso, re ka haha sesebediswa entsoeng ka serōki ho khotsofatsa litlhoko tsa boleng ba lihlahisoa tsa hao.

3.E na le lisebelisoa tse ikhethang tse nang le mechine e holimo ea ho lahla le mechine ea CNC, e re fa monyetla oa ho hlahisa lihlahisoa tse nepahetseng tse phahameng.

4.Tshehetso e matla ea botekgeniki ea ts'ebeliso ho moreki mokhahlelong oa nts'etsopele ea projeke e fapaneng le bafani ba bang.Morero oa rona ke ho aha tšebelisano ea nako e telele le bareki ba rona.