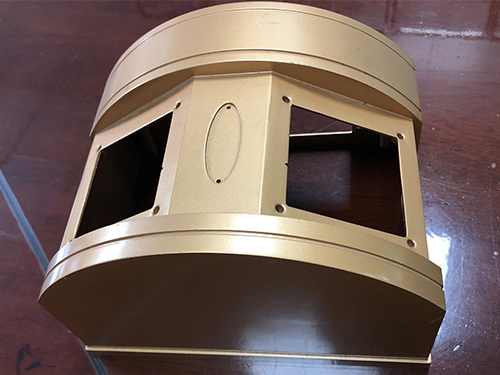

1. Formwork

1. Nzvimbo yekunze inodiwa kuti ive yakajeka uye yakatsetseka. Maburi maviri epunch anowedzerwa kumberi nekumashure mold mafuremu. Ngwarira kune nzvimbo dzisina kuiswa kudzivirira zvikamu kubva pakudonha.

2. Iyo AB plate mold frame inofananidzwa nemumwe kuti iite 0.1-0.15, uye kubhururuka kwemvura inobhururuka kunowedzerwa kudzivirira aluminium kuti irege kubhururuka kunze uye kukuvadza vanhu.

3. Kuti udzivise template kubva pakuremara, kanenge ita makoramu maviri ekutsigira, imwe pane shunt koni, uye imwe pane shunt koni. Chenjerera kuti usapindira nezvimwe zvikamu.

4. Mushonga unowedzera 2-4 mabheji epakati uye mabheji epakati, uye rutivi rwepakati rwepakati rinonyanya kuitwa nemuganhu.

5. Indiro yepasi ye mold inofanira kunge yakazaruka kuti iite kuti kupisa kunopisa.

6. Makona mana emuumbi anofanira kutemwa kuti arege kurova positi yakasvibirira panguva yekuiswa.

7. Tafura yemukati megomba remhete yekumisikidza inodiwa kuti iite nitrided mushure mekukuya kwemukati uye kukwenenzverwa pamwe negwara rekuburitsa.

8. Kureba kubva pasi pemhete inotonhorera pamusoro pechindori chekumisikidza kusvika pamusoro peiyo splitter cone kazhinji yakaenzana nehupamhi hwekeke. Pane nzira mbiri dzekugadzirisa iyi mhete yekutonhora: welding uye kudziyisa nekutsikirira.

9. Iyo shunt cone inofanira kutonhodzwa nekutakura mvura, uye 25-30mm kure nepamusoro pe shunt cone.

10. Iwo mana anotungamira post maburi e mold base anofanira kunge ari prying grooves ane hudzamu hwe8-10mm.

.

12. Kuti zvive nyore kubviswa kwekuiswa kwemukati mold, gomba rinogona kuwedzerwa pamusoro pemuumbi, uye ipapo mashoma mashoma asina musoro anogona kuunganidzwa, kuitira kuti zvive nyore kuparadzanisa uye kutsiva kuiswa.

13. Makomba ekusimudza anofanira kunge ari M30 uye 45 yakadzika, uye 2 kumusoro.

14. Chipfuramabwe chekunze chinofanira kunge chakashongedzerwa nechifukidziro chekudzivirira chitubu kudzivirira chitubu kubva pakuremara.

.

2. Mold yemukati, isa

1. Ita kurapa kwekushungurudzika kusati kwaitwa kupisa mushure mekugadzirisa. General aruminiyamu chiwanikwa chinodzima HRC45+/-1°C, zingi chiwanikwa chinodzima HRC46+/-1-1°C

2. Kushivirira kwakakodzera kwemukati mold: Kazhinji, inofanira kuva inenge 0.05-0.08mm idiki pane mold furemu, uye inogona kutorwa nyore nyore uye kuiswa muforomu nemhete yekusimudza.

Iyo thimble inokodzera kushivirira: iyo thimble clearance yehukuru kupfuura kana yakaenzana ne8mm ndeye 0.05mm,

Iyo gap yetimble yeisingasviki kana yakaenzana ne6mm ndeye 0.025mm.

3. Makona ese akarurama uye acute pane mold yemukati anofanira kunge ari pamusoro peR0.5mm.

4. Shandisa flat-blade screws kuvhara maburi akawandisa pamusoro pemukati mold.

3. Mumhanyi uye slag discharge system design

1. Nzira huru yekuyerera yekeke rejira pane shunt koni inofanira kunge iri mukati me1/3 yenzvimbo yedenderedzwa. Nenzira iyi, nzvimbo yekuparadzanisa inovharwa isati inotonhora ichipinda mugomba.

2. Mugero mukuru pamusoro pekoni yakaparadzana inofanira kuitwa mu "W" chimiro, uye hupamhi hwekeke hunofanira kuva 15-20mm.

3. Kazhinji, kureba kwemumhanyi mukuru kunofanira kuva 30-35mm, uye mold inofanira kuva 5-10 ° kune rumwe rutivi.

4. Kazhinji, nzira yemuchinjikwa ndiyo yakanakisisa kukotama uye kuita nhanho dzinopfuura 2 kudzivirira zvinhu zvinotonhora kuti zvipinde mumhango kuburikidza nemuchinjiko wekuyerera, zvichiita kuti mitsara inotonhora inovhara pamusoro pechigadzirwa.

5. Kazhinji, zviri nani kuwedzera 2 buffers panzvimbo yegedhi apo nzira yemuchinjikwa inoyerera inopinda muchigadzirwa, kuitira kuti zvinhu zvinotonhora zvivharwe zvachose kunze kwegomba.

6. Kazhinji, chiyero chetimble pasi pemumhanyi mukuru chinofanira kuumbwa, uye chinofanira kunge chiri pamusoro peR2.

7. Nheyo inoputika kune rumwe rutivi rwomumhanyi mukuru inofanira kudziviswa, uye bhegi re slag kune rumwe rutivi rwomumhanyi mukuru rinofanira kuva marara kutanga, uye wozozarura maererano nemamiriro acho ezvinhu.

8. Slag bhegi iri nani kushandisa ndege yedare, muchinjikwa-sectional chimiro che semicircle, uye mvura inopinza uye groove inopera inoparadzaniswa ne 1/3. Mvura inopinza yebhegi ye slag inofanirawo kuregwa.

9. Slot yekupera inofanira kuderedzwa uye yakashandurwa zvakanaka, ichitevera mitemo ye "3.2.1".

10. Kuti zvive nyore kugadzirisa, gedhi riri pamharadzano yenzira yakananga yekuyerera uye chigadzirwa chinofanira kuregwa, uye hazvisi nyore kurasikirwa nenyama panguva yekugadzira.

4. Core kudhonza michina

1. Inotsvedza inofanira kugadzirwa neinenge imwe chete inorembera buri panzvimbo yepamusoro nepasi kuti ifambise disassembly uye kusangana.

2. Pasi pemuteresi inofanira kunge iri chidimbu chekucheka, uye jira rinoputika rinofanira kuitwa muzvikamu zviviri zve 8-12mm yakakwirira kudarika yepasi mold base surface kuitira kuti kucheneswa kwealuminium slag panguva yekugadzirwa.

3. Bead yeslider inofanirwa kunge iri groove isingapfeke, iri 45° ine core yekudhonza direction.

4. Iyo inotsvedza nzira inofanirwa kuve yakasununguka mukutungamira uye kutsvedza, yakagadzikana mukufamba, ine clearance ye0.08--0.12MM.

5. Mushure mokunge mold yakavharwa, slider uye kuvhara kwekuvhara kunofanira kusimbiswa zvakasimba, nzvimbo yekubatana haisi pasi pezvikamu zviviri kubva muzvitatu, uye ine imwe prestress.

If you'd like to speak to a member of the Anebon team for Aluminum Casting,CNC Machined Custom Service,CNC Turning Alloy, please get in touch at info@anebon.com

Nguva yekutumira: Feb-25-2021