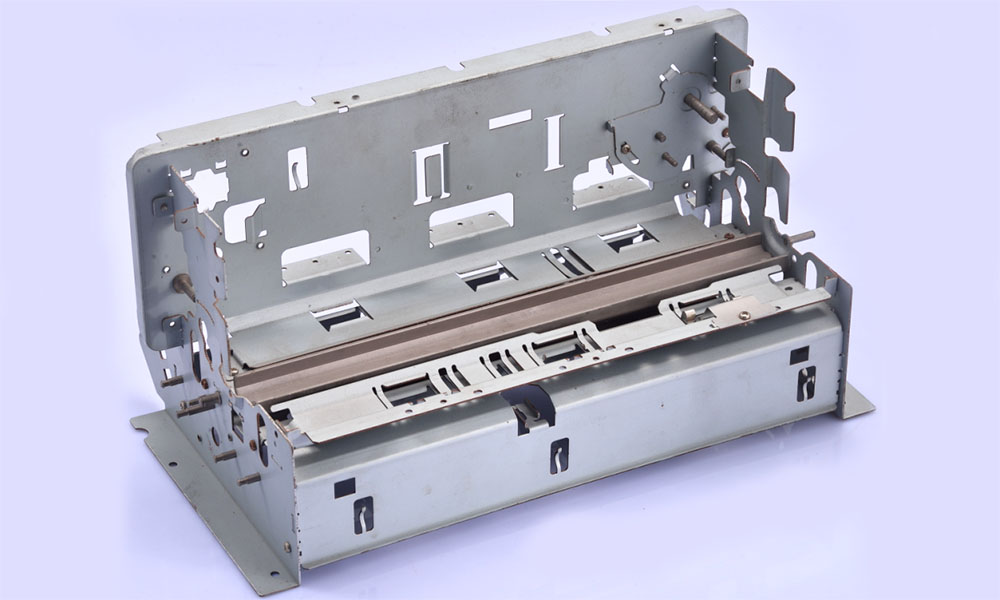

Stamping Logam Otomotif

Bagian stamping utamane dibentuk kanthi stamping lan stamping lembaran logam utawa non-logam kanthi tekanan pers. Fitur utama minangka nderek:

Bagian stampingdiprodhuksi dening stamping ing premis saka konsumsi bahan kurang. Bagean kasebut entheng bobot lan apik ing kaku, lan sawise materi lembaran plastik cacat, struktur internal logam wis apik, lan kekuatan bagian stamping wis apik.

| Bahan sing kasedhiya | Aluminium (LM4, LM6, LM24, LM25, LM27, A360, A380, A383 lan A413) Seng (ZA3, ZA5, AC43A, AG40A, AC41A, AG40B) Paduan tembaga lan magnesium |

| Proses Produksi | 1, Proses: Die Casting / Sand Casting / Gravity Casting2, Mesin Sekunder: CNC ngowahi, Milling, Drilling, Grinding, Majelis kanggo Packing |

| Pangobatan lumahing | Getaran Grinding, Ball blasting, Anodization, Plating, Painting, Coating, Polishing, Disikat, Chrome Plating, Nikel Plating, E-Coating etc |

| Peralatan Inspeksi | Mesin Ukur Koordinat CMM 3D, Mesin Ukur Gambar Manual 2.5D, Mesin Uji Semprotan Garam, Deteksi Detektor Optik CCD, Arm CMM, Hardness Tester, Tester Dhuwur, Mikrometer, Digital Calliper, Go-No Go Measure Gauge, Ring Gauge, Plug Gauge dll . |

| Kualitas | ISO 9001:2008, Inspeksi FA, PPAP, Data CPK lsp. |

Tulis pesen sampeyan ing kene lan kirimake menyang kita