Ụkpụrụ na-arụ ọrụ nke nhazi polygon

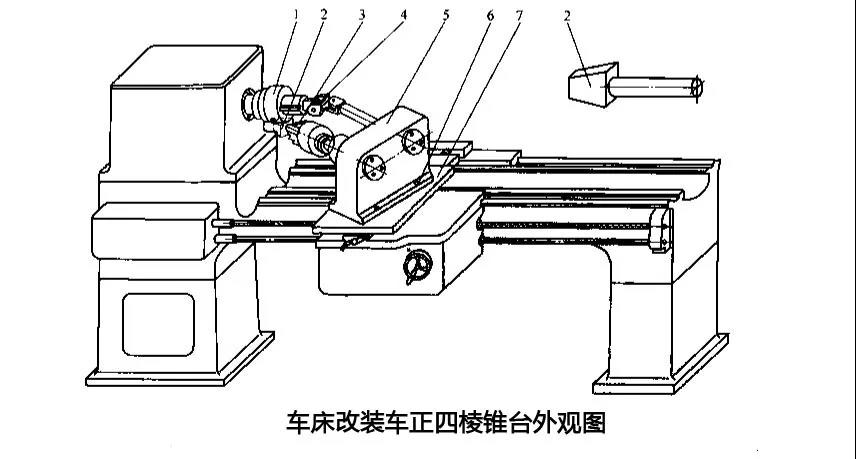

Maka nhazi polygonal workpieces na lathe, a ga-etinye ngwaọrụ pụrụ iche dị ka egosiri na ọnụ ọgụgụ ahụ.

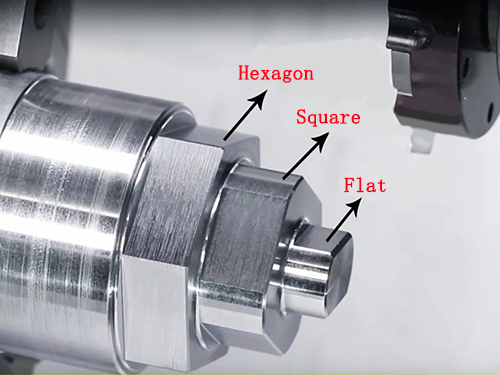

1-Cutter 2-Workpiece 3-Chuck 4-Universal njikọta 5-Nfefe 6-Kpọgide 7-Bottom efere.

Mgbe mbịne, ọ na-arụnyere na n'etiti slide efere ime ka workpiece na ngwá ọrụ bugharia n'otu ụzọ, na ọsọ ruru mmekọrịta dị n'etiti ngwá ọrụ na workpiece na a ụfọdụ ọnụ ọgụgụ nke ngwá ọrụ isi na-eji na-aghọta na ikwu ije nke. ngwá ọrụ na workpiece, nke mere na ọ na-ghọtara dị ka mmepe iwu n'elu akpụ, mezue nhazi nke square, hexagon, mgbe triangle, trapezoid, drum, n'úkwù, flat, diamond, oge ufodu polygon na polygonal workpiece na taper.

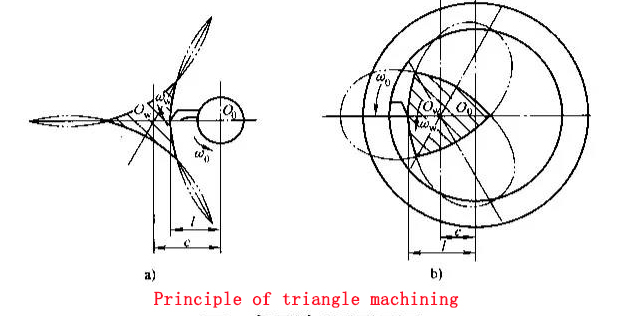

Dịka ọmụmaatụ, mgbe ị na-edozi triangle equilateral, nnyefe nke ngwá ọrụ na workpiece bụ i = 3, ya mere, trajectory nke n'ọnụ ngwá ọrụ metụtara axis nke workpiece bụ a na-emechi ugboro ugboro ugboro n'oge usoro ịkpụ, na akụkụ etiti gbara okirikiri ahụ na-etolite triangle dị nso.

Ọ bụrụ na workpiece axis bụ n'èzí ngwá ọrụ n'ọnụ ngagharị okirikiri, triangle a na-akpọ "mpụta ọnwụ usoro" gosiri na Figure a; ma ọ bụrụ na workpiece axis bụ n'ime ngwá ọrụ n'ọnụ ngagharị okirikiri, ọ na-akpọ "n'ime ọnwụ usoro", na triangle na-egosi dị ka Figure b na-egosi.

Enwere ike ịhụ ya site na ọnụ ọgụgụ triangular ndị a gosipụtara, ma a na-eji ụzọ mpụta mpụta ma ọ bụ usoro ịkpụ n'ime ya, n'elu ebe a na-arụ ọrụ triangular a na-arụ ọrụ abụghị nke dị larịị, kama ọ bụ ihu arc okirikiri bụ nke dị larịị. Ya mere, usoro nke ịtụgharị polygon ndị a kpọtụrụ aha n'elu bụ naanị Enwere ike iji ya mee ihe na nhazi nke na-adịghị achọ elu elu elu.

2 Okwu mmalite nke ngwa ndị a na-ejikarị eme ihe

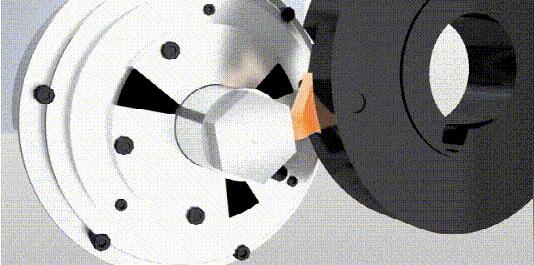

Okwu mmeghe nke dị n'elu bụ usoro ọdịnala, na n'ime ngwa ndị dị irè, e nwere ụdị ihe ngosi dị iche iche nke ngwá ọrụ, ụkpụrụ bụ otu, ma na ntinye nke ụkpụrụ ahụ, ngwá ọrụ ahụ na-eme isi ihe na mkpịsị aka, workpiece na-eme ihe enyemaka inyeaka. , na N'ime ngwa bara uru, a na-ebugharị workpiece na spindle.

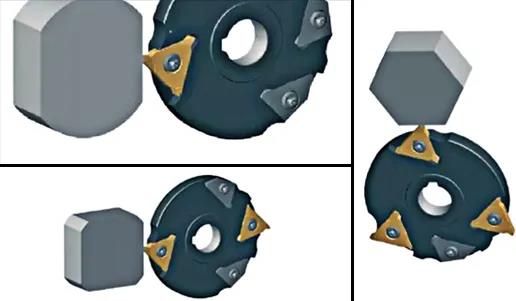

Na ntụgharị polygon, a na-eji diski na-efe efe na-egbutu polygons (n'akụkụ atọ ruo asatọ) n'akụkụ akụkụ axisymmetric workpiece. Mpempe ọrụ (isi spindle) na ngwá ọrụ na-agbagharị agbagharị (isi onye na-efe efe na-efe efe) na-arụkọ ọrụ ọnụ n'ụzọ jikọtara ya na igwe na-arụ ọrụ.

Ọnụ ọgụgụ nke ịkpụ n'elu na-adabere na nnyefe nnyefe na ọnụ ọgụgụ nke mbepụ na ngwá ọrụ ịkpụ. Ntuziaka nke ntụgharị nke workpiece na ngwá ọrụ dị iche.

Na-ahazi Hexagon

Nhazi akụkụ anọ

A na-eji onye na-egbu osisi nke nwere eriri abụọ na-egbutu akụkụ anọ, a na-eji onye na-egbu osisi nke nwere eriri atọ na-egbutu hexagons, wdg. arcs nwere ike ịpụta n'elu nke workpiece.

N'ihi nke a ụkpụrụ, ihe ndepụta trajectory eme site n'ọnụ n'ọnụ bụ kpọmkwem ellipse, ma usoro nke emejuputa atumatu na ike elu nke wrench bụ akụkụ nke ellipse na ibu radius nke curvature, n'ihi ya, ọ dịghị emetụta mgbakọ nke na-agbatị na ịtọpụ. arụ ọrụ.

We are a reliable supplier and professional in CNC service. If you need our assistance please contact me at info@anebon.com.

Oge nzipu: Eprel-29-2020