1. Ụdị

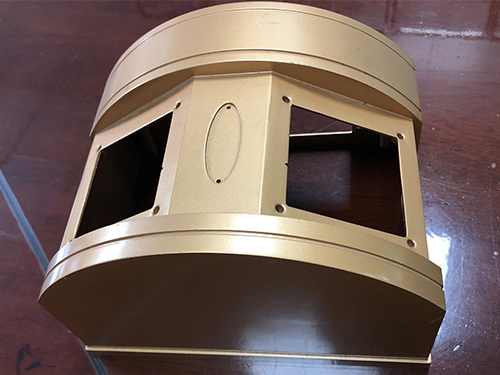

1. A na-achọ ka elu elu dị elu na-egbuke egbuke ma dị larịị. A na-agbakwunye oghere ntụmadị abụọ n'ihu na n'azụ okpokolo agba. Lezienụ anya na ebe ndị na-enweghị ntinye iji gbochie akụkụ ndị ahụ ka ọ ghara ịdaba.

2. A na-ejikọta etiti AB efere na-akpụ akpụ na ibe ya iji mee 0.1-0.15, a na-agbakwunyekwa ihe mgbochi mmiri na-efe efe iji gbochie aluminum ka ọ na-efe efe ma na-emerụ ndị mmadụ ahụ.

3. Iji gbochie template site n'ịgbanwe, ọ dịkarịa ala mee ogidi nkwado abụọ, otu na cone shunt, na otu na cone shunt. Kpachara anya ka ị ghara itinye aka na akụkụ ndị ọzọ.

4. Akpụkpọ ahụ na-agbakwunye 2-4 n'etiti etiti na etiti etiti, na akụkụ nke etiti etiti ka a na-eji oke.

5. Efere ala nke ebu ahụ ga-emegherịrị iji mee ka ikpochapụ okpomọkụ dị mfe.

6. A ga-egbutu akụkụ anọ nke ebu ahụ iji gbochie ya ịkụ akwụkwọ ndụ akwụkwọ ndụ n'oge echichi.

7. Tebụl oghere dị n'ime nke mgbanaka ọnọdụ a chọrọ ka nitrided mgbe egweri n'ime ya ma na-egbuke egbuke n'akụkụ ụzọ ọpụpụ.

8. Ogologo site na ala nke mgbanaka jụrụ oyi n'elu mgbanaka ntinye na elu nke cone splitter bụ n'ozuzu hà nhata nke achicha ahụ. Enwere ụzọ abụọ iji dozie mgbanaka jụrụ oyi: ịgbado ọkụ na kpo oku na ịpị.

9. A ghaghị ime ka cone shunt dị jụụ site na-ebufe mmiri, na 25-30mm pụọ na elu nke shunt cone.

10. The anọ ndu post oghere nke ebu isi kwesịrị prying grooves na omimi nke 8-10mm.

11. The ebu isi ga-emenyụ na iwe, ọkacha mma a adịgboroja ebu isi.

12. Iji mee ka mwepụ nke ntinye nke ihe dị n'ime ya dị mfe, enwere ike ịgbakwunye oghere n'elu ihe nkedo ahụ, mgbe ahụ, a ga-anakọta skru ole na ole na-enweghị isi, nke mere na ọ dị mfe ịkwasa ma dochie ihe ntinye.

13. Oghere ndị na-ebuli elu ga-adị ma ọ dịkarịa ala M30 na 45 dị omimi, ma ọ dịkarịa ala 2 n'elu.

14. Ebè nke dị n'èzí ga-enwerịrị ihe mkpuchi mmiri iji gbochie mmiri na-emebi.

15. Elu nke dị elu karịa elu nke isi ihe na-akpụ akpụ ma dị mkpa na kọntaktị na ala kwesịrị ịgbakwunye ogidi nkwado.

2. Ime ime, tinye

1. Mee ọgwụgwọ mgbakasị ahụ tupu ọgwụgwọ okpomọkụ mgbe nhazi. General aluminum alloy quenching HRC45+/-1°C, zinc alloy quenching HRC46+/-1-1°C

2. The kwesịrị ekwesị ndidi nke n'ime ebu: N'ozuzu, ọ kwesịrị ịbụ banyere 0.05-0.08mm obere karịa ebu etiti, na ọ nwere ike mfe wepụ na-etinye n'ime ebu osisi na-ebuli mgbanaka.

The thimble dabara ndidi: thimble mkpochapụ nke ukwuu karịa ma ọ bụ hà 8mm bụ 0.05mm,

The thimble oghere nke na-erughị ma ọ bụ hà 6mm bụ 0.025mm.

3. Akụkụ niile ziri ezi na nnukwu akụkụ dị n'ime ebu ga-adịrịrị R0.5mm.

4. Jiri kposara agụba dị larịị gbochie oghere ndị dị n'elu nke ime ime.

3. Nhazi usoro ịgba ọsọ na slag

1. Ụzọ isi na-asọ asọ nke achicha akwa na cone shunt kwesịrị ịdị n'ime 1/3 nke elu elu nke gburugburu. N'ụzọ dị otú a, a na-emechi elu nkewa tupu ihe oyi abanye ngwa ngwa n'ime oghere.

2. Isi ọwa dị n'elu cone gbawara agbawa kwesịrị ime ka ọ bụrụ ọdịdị "W", na ọkpụrụkpụ nke achicha ahụ kwesịrị ịbụ 15-20mm.

3. N'ozuzu, ogologo nke onye na-agba ọsọ kwesịrị ịbụ 30-35mm, na ebu kwesịrị ịbụ 5-10 ° n'otu akụkụ.

4. N'ozuzu, ọwa mmiri na-agafe agafe kacha mma na-ehulata ma mee ihe karịrị 2 nzọụkwụ iji gbochie ihe oyi na-eme ka ọ ghara ịbanye n'ime oghere site na ọwa mmiri na-asọ asọ, na-eme ka ahịrị mgbochi oyi dị n'elu ngwaahịa ahụ.

5. N'ozuzu, ọ kacha mma ịgbakwunye 2 buffers n'ọnụ ụzọ ámá ebe cross-flow channel na-abanye n'ime ngwaahịa ahụ, nke mere na ihe oyi na-ekpo ọkụ na-egbochi kpamkpam site na oghere.

6. N'ozuzu, a ghaghị ịkpụzi ọkwa nke thimble n'okpuru onye na-agba ọsọ, ọ ga-adịkwa n'elu R2.

7. A ghaghị izere isi ihe na-apụta n'akụkụ nke ọzọ nke onye na-agba ọsọ, na akpa slag dị n'akụkụ nke ọzọ nke onye na-agba ọsọ kwesịrị ịbụ ihe mkpofu na mbụ, wee mepee dịka ọnọdụ ahụ si dị.

8. Akpa slag kacha mma iji ụgbọ elu nke ụlọ ikpe ahụ, akụkụ nke akụkụ nke akụkụ nke ọkara, na ntinye mmiri na ikpo ọkụ na-ekewa site na 1/3. Ekwesịrị ịwụpụ mmiri mmiri nke akpa slag.

9. Ekwesịrị ịbelata oghere nke iyuzucha ma gbanwee nke ọma, na-agbaso iwu nke "3.2.1".

10. Iji kwado nhazi, ọnụ ụzọ ámá dị na nkwụsị nke ọwa mmiri na-asọpụta kpọmkwem na ngwaahịa ahụ kwesịrị ịwụpụ, ọ dịghịkwa mfe ịhapụ anụ n'oge nhazi.

4. Usoro ịdọrọ isi

1. A ghaghị ime ihe mmịfe ahụ ma ọ dịkarịa ala otu oghere anwụ anwụ n'elu elu na nke dị ala iji kwado disassembly na mgbakọ.

2. Ala nke ihe mmịfe ahụ kwesịrị ịbụ ebe a na-egbutu, na eriri na-eguzogide ọgwụ kwesịrị ime ka ọ bụrụ akụkụ 2 nke 8-12mm dị elu karịa ala ala ebu n'elu iji kwado ihicha nke aluminum slag n'oge mmepụta.

3. The bead nke ihe mmịfe kwesịrị ịbụ a eyi na-eguzogide uzo, nke bụ 45° na isi na-adọta ntụziaka.

4. Usoro ihe eji eme ihe kwesịrị ịdị na-agbanwe na nduzi na ịkwagharị, kwụsie ike na mmegharị, na nkwụsị nke 0.08--0.12MM.

5. Mgbe e mechibidoro ebu ahụ, a ga-ejigide ihe mmịfe na mgbochi mkpọchi, ebe kọntaktị adịghị ihe na-erughị ụzọ abụọ n'ụzọ atọ, ma nwee ụfọdụ prestress.

If you'd like to speak to a member of the Anebon team for Aluminum Casting,CNC Machined Custom Service,CNC Turning Alloy, please get in touch at info@anebon.com

Oge nzipu: Feb-25-2021