1. Formwork

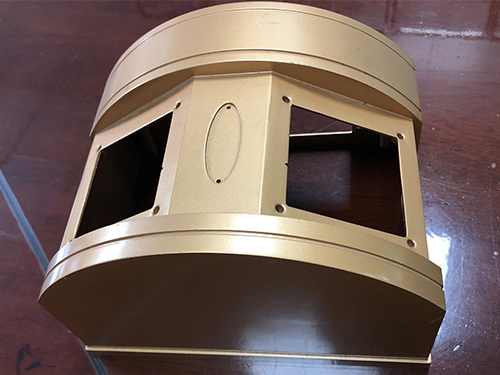

1. Lub sab nrauv yuav tsum tau ua kom ci thiab tiaj tus. Ob lub qhov punch yog ntxiv rau pem hauv ntej thiab nram qab pwm ncej. Ua tib zoo saib xyuas qhov chaw uas tsis muaj qhov ntxig ntxig los tiv thaiv cov khoom los ntawm kev poob.

2. Lub AB phaj pwm thav duab yog sib xyaw ua ke los ua 0.1-0.15, thiab cov baffle dej ya tau ntxiv los tiv thaiv cov txhuas tsis ya tawm thiab ua phem rau tib neeg.

3. Txhawm rau tiv thaiv tus qauv los ntawm deforming, yam tsawg kawg ua ob kab kev txhawb nqa, ib qho ntawm shunt cone, thiab ib qho ntawm shunt cone. Ceev faj kom tsis txhob cuam tshuam lwm qhov chaw.

4. Cov pwm ntxiv 2-4 nruab nrab brackets thiab nruab nrab bracket, thiab nruab nrab bracket sab yog qhov zoo tshaj plaws nrog rau kev txwv.

5. Lub phaj hauv qab ntawm cov pwm yuav tsum tau qhib kom yooj yim rau cua sov dissipation.

6. Cov plaub fab ntawm cov pwm yuav tsum raug txiav kom tsis txhob cuam tshuam cov ncej ntsuab thaum lub sij hawm installation.

7. Lub puab lub rooj ntawm lub nplhaib muab tso rau hauv lub nplhaib yuav tsum tau nitrided tom qab sib tsoo thiab polished raws li ejection kev taw qhia.

8. Qhov ntev ntawm lub hauv qab ntawm lub nplhaib txias rau ntawm qhov chaw ntawm lub nplhaib mus rau saum npoo ntawm lub khob noom cookie yog feem ntau sib npaug rau lub thickness ntawm lub ncuav mog qab zib. Muaj ob txoj hauv kev los kho lub nplhaib txias no: vuam thiab cua sov thiab nias.

9. Lub khob hliav qab shunt yuav tsum tau txias los ntawm kev thauj cov dej, thiab 25-30mm deb ntawm qhov saum npoo ntawm shunt cone.

10. Plaub daim ntawv qhia ncej qhov ntawm lub hauv paus pwm yuav tsum yog prying grooves nrog ib tug tob ntawm 8-10mm.

11. Lub hauv paus pwm yuav tsum tau quenched thiab tempered, nyiam dua yog forged pwm puag.

12. Txhawm rau kom yooj yim tshem tawm cov ntxig ntawm cov pwm puab, ib lub qhov tuaj yeem ntxiv rau saum npoo ntawm cov pwm, thiab tom qab ntawd muab ob peb lub taub hau tsis muaj hau, kom nws yooj yim rau disassemble thiab hloov cov inserts.

13. Lub hoisting qhov yuav tsum muaj tsawg kawg yog M30 thiab 45 sib sib zog nqus, thiab tsawg kawg yog 2 nyob rau saum.

14. Lub slingshot sab nraud yuav tsum tau nruab nrog lub caij nplooj ntoos hlav tiv thaiv npog tiv thaiv lub caij nplooj ntoos hlav los ntawm deforming.

15. Qhov saum npoo uas siab tshaj qhov saum npoo ntawm lub hauv paus pwm thiab yuav tsum tau nyob rau hauv kev sib cuag nrog hauv av yuav tsum tau muab ntxiv nrog cov kev txhawb nqa txhua.

2. puab pwm, ntxig

1. Ua kev kho kev ntxhov siab ua ntej kev kho cua sov tom qab ua tiav. General aluminium alloy quenching HRC45 +/-1 ° C, zinc alloy quenching HRC46 +/-1-1 ° C

2. Qhov haum rau pwm sab hauv: Feem ntau, nws yuav tsum yog li 0.05-0.08mm me dua li cov pwm pwm, thiab nws tuaj yeem yooj yim tshem tawm thiab muab tso rau hauv pwm nrog lub nplhaib nqa.

Lub thimble haum kam rau ua: lub thimble clearance ntau dua los yog sib npaug rau 8mm yog 0.05mm,

Lub thimble qhov sib txawv ntawm tsawg dua los yog sib npaug ntawm 6mm yog 0.025mm.

3. Tag nrho txoj cai thiab mob lub kaum sab xis ntawm lub puab pwm yuav tsum yog tshaj R0.5mm.

4. Siv cov ntsia hlau tiaj tiaj los thaiv cov qhov ntau dhau ntawm cov pwm sab hauv.

3. Khiav thiab slag tawm qhov system tsim

1. Txoj kev ntws tseem ceeb ntawm cov ncuav mog qab zib ntawm lub khob cij shunt yuav tsum tsis pub dhau 1/3 ntawm thaj tsam ntawm lub voj voog. Nyob rau hauv txoj kev no, qhov chaw seem yog kaw ua ntej cov khoom txias sai nkag mus rau hauv kab noj hniav.

2. Lub ntsiab channel saum toj ntawm lub khob noom cookie yuav tsum tau ua "W" zoo, thiab lub thickness ntawm lub ncuav mog qab zib yuav tsum yog 15-20mm.

3. Feem ntau, qhov ntev ntawm lub ntsiab khiav yuav tsum yog 30-35mm, thiab pwm yuav tsum yog 5-10 ° ntawm ib sab.

4. Feem ntau, txoj kab hla hla yog qhov zoo tshaj plaws los khoov thiab ua ntau tshaj 2 kauj ruam los tiv thaiv cov khoom txias los ntawm kev nkag mus rau hauv kab noj hniav los ntawm cov kab hla hla, uas ua rau cov kab mob khaub thuas barrier rau saum npoo ntawm cov khoom.

5. Feem ntau, nws yog qhov zoo tshaj rau ntxiv 2 buffers ntawm lub rooj vag txoj hauj lwm qhov twg tus ntoo khaub lig ntws channel nkag mus rau hauv cov khoom, kom cov khoom txias yog tag nrho thaiv tawm ntawm cov kab noj hniav.

6. Feem ntau, theem ntawm lub thimble nyob rau hauv lub ntsiab khiav yuav tsum moulded, thiab nws yuav tsum yog siab tshaj R2.

7. Cov tub ntxhais protruding nyob rau sab nraud ntawm tus neeg khiav dej num tseem ceeb yuav tsum tau zam, thiab lub hnab slag nyob rau sab nraud ntawm lub ntsiab khiav yuav tsum tau khib nyiab ua ntej, thiab tom qab ntawd qhib raws li qhov xwm txheej.

8. Lub hnab slag yog qhov zoo tshaj plaws rau kev siv lub dav hlau ntawm lub tsev hais plaub, qhov sib txawv ntawm cov duab ntawm ib lub voj voog, thiab cov dej nkag thiab cov qhov tso tawm yog sib cais los ntawm 1/3. Cov dej nkag ntawm lub hnab slag yuav tsum tau hla.

9. Lub qhov tso pa tawm yuav tsum tau txo qis thiab ua haujlwm zoo, ua raws li cov cai ntawm "3.2.1".

10. Txhawm rau kom yooj yim rau kev ua haujlwm, lub rooj vag ntawm qhov sib txuas ntawm qhov ncaj qha ntws channel thiab cov khoom yuav tsum tau hla, thiab nws tsis yooj yim rau cov nqaij poob thaum lub sijhawm ua haujlwm tom qab.

4. Core rub mechanism

1. Lub slider yuav tsum tau ua nrog tsawg kawg ib lub qhov dai tuag rau ntawm qhov chaw sab saud thiab qis kom yooj yim rau kev tshem tawm thiab sib dhos.

2. Lub hauv qab ntawm lub slider yuav tsum yog ib tug txiav trough, thiab hnav-resistant sawb yuav tsum tau ua rau 2 daim ntawm 8-12mm siab tshaj lub hauv qab pwm puag nto los pab txhawb kev ntxuav ntawm txhuas slag thaum lub sij hawm tsim khoom.

3. Lub hlaws ntawm lub slider yuav tsum yog ib qho hnav-tiv taus zawj, uas yog 45 ° nrog cov tub ntxhais rub kev taw qhia

4. Cov txheej txheem zawv zawg yuav tsum hloov pauv hauv kev taw qhia thiab zawv zawg, ruaj khov hauv kev txav, nrog kev tshem tawm ntawm 0.08--0.12MM.

5. Tom qab cov pwm raug kaw lawm, lub slider thiab lub kaw lus kaw yuav tsum tau nias kom nruj, qhov chaw tiv thaiv tsis pub tsawg tshaj li ob feem peb, thiab muaj qee yam prestress.

If you'd like to speak to a member of the Anebon team for Aluminum Casting,CNC Machined Custom Service,CNC Turning Alloy, please get in touch at info@anebon.com

Post lub sij hawm: Feb-25-2021