1. Tsarin tsari

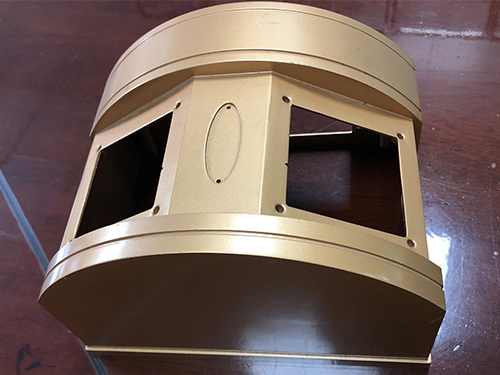

1. Ana buƙatar saman waje ya zama mai haske da lebur. Ana ƙara ramukan naushi biyu zuwa firam ɗin ƙira na gaba da na baya. Kula da wuraren da babu abin da aka saka don hana sassa daga faɗuwa.

2. An daidaita firam ɗin AB plate mold da juna don yin 0.1-0.15, kuma ana ƙara baffle ruwa mai tashi don hana aluminum daga tashi da cutar da mutane.

3. Don hana samfurin daga lalacewa, aƙalla yi ginshiƙan tallafi guda biyu, ɗaya a kan mazugi na shunt, ɗaya kuma a kan mazugi na shunt. Yi hankali kada ku tsoma baki tare da wasu sassa.

4. Ƙwararren yana ƙara 2-4 na tsakiya na tsakiya da tsaka-tsakin tsaka-tsaki, kuma gefen tsakiya ya fi dacewa da iyaka.

5. Dole ne farantin ƙasa na mold ya buɗe don sauƙaƙe zafi.

6. Ya kamata a yanke kusurwoyi huɗu na mold don hana shi daga bugun kore a lokacin shigarwa.

7. Ana buƙatar teburin rami na ciki na zoben sakawa da za a nitrided bayan niƙa na ciki da goge tare da hanyar fitarwa.

8. Tsawon daga kasan zobe mai sanyaya a saman zoben sanyawa zuwa saman mazugi mai tsaga yawanci daidai yake da kauri na cake. Akwai hanyoyi guda biyu don gyara wannan zoben sanyaya: walda da dumama da latsawa.

9. Dole ne a kwantar da mazugi na shunt ta hanyar jigilar ruwa, kuma 25-30mm daga saman mazugi na shunt.

10. The hudu jagora post ramuka na mold tushe ya zama prying grooves da zurfin 8-10mm.

11. Dole ne a kashe gindin ƙirƙira da zafin rai, zai fi dacewa da ƙirƙira ƙirƙira tushe.

12. Don sauƙaƙe cire abubuwan da aka sanya na ciki na ciki, za'a iya ƙara rami a saman ƙirar, sa'an nan kuma za'a iya tattara 'yan ƙwanƙwasa marasa kai, don haka ya dace don kwancewa da maye gurbin abubuwan da aka saka.

13. Dole ne ramukan ɗagawa su kasance aƙalla M30 da zurfin 45, kuma aƙalla 2 a saman.

14. Dole ne a sanya majajjawa na waje tare da murfin kariya na bazara don hana bazara daga lalacewa.

15. Ya kamata a kara daɗaɗɗen da ya fi girma fiye da tushe na tushe kuma yana buƙatar kasancewa tare da ƙasa tare da ginshiƙan tallafi.

2. Tsarin ciki, saka

1. Yi maganin damuwa kafin maganin zafi bayan aiki. Janar aluminum gami quenching HRC45+/-1°C, zinc gami quenching HRC46+/-1-1°C

2. A Fit haƙuri na ciki mold: Gabaɗaya, ya kamata ya zama game da 0.05-0.08mm karami fiye da mold frame, kuma shi za a iya sauƙi cire da kuma saka a cikin mold frame tare da dagawa zobe.

Haƙurin juzu'i na thimble: ƙwanƙwasa mafi girma ko daidai da 8mm shine 0.05mm,

Tazarar ƙasa da ko daidai da 6mm shine 0.025mm.

3. Duk madaidaitan kusurwoyi masu ƙarfi a kan ƙirar ciki dole ne su wuce R0.5mm.

4. Yi amfani da sukurori mai lebur don toshe ramukan da suka wuce gona da iri a saman ƙirar ciki.

3. Tsarin tsarin fitarwa na Runner da slag

1. Babban hanyar tafiya na kek na masana'anta a kan mazugi shunt ya kamata ya kasance cikin 1/3 na farfajiyar da'irar. Ta wannan hanyar, an rufe farfajiyar rabuwa kafin kayan sanyi ya shiga cikin rami da sauri.

2. Babban tashar da ke sama da mazugi ya kamata a yi shi a cikin siffar "W", kuma kauri na cake ya zama 15-20mm.

3. Gabaɗaya, tsawon babban mai gudu ya kamata ya zama 30-35mm, kuma ƙirar ya zama 5-10 ° a gefe ɗaya.

4. Gabaɗaya, tashar tashar giciye ta fi dacewa don tanƙwara da yin matakai fiye da 2 don hana kayan sanyi daga shiga cikin rami ta hanyar tashar giciye, yana haifar da layin shinge mai sanyi a saman samfurin.

5. Gabaɗaya, yana da kyau a ƙara 2 buffers a ƙofar kofa inda tashar giciye ta shiga cikin samfurin, don haka an katange kayan sanyi daga cikin rami.

6. Gaba ɗaya, matakin thimble a ƙarƙashin babban mai gudu dole ne a tsara shi, kuma dole ne ya kasance sama da R2.

7. Dole ne a guje wa ƙwanƙwasa mai tasowa a gefe na babban mai gudu, kuma jakar da ke gefe na babban mai gudu ya kamata ya zama datti da farko, sannan a bude bisa ga yanayin.

8. Jakar slag ya fi dacewa don amfani da jirgin saman kotu, siffar giciye na tsaka-tsakin tsaka-tsakin, da ruwa mai shiga ruwa da tsattsauran raƙuman ruwa sun rabu da 1/3. Hakanan ya kamata a tsallake mashigar ruwa na jakar slag.

9. Ya kamata a rangwame ramin shaye-shaye kuma a canza shi cikin sauƙi, bin ka'idodin "3.2.1".

10. Don sauƙaƙe aiki, ƙofar da ke kusa da tashar tashar tashar kai tsaye da samfurin ya kamata a tsallake shi, kuma ba shi da sauƙi a rasa nama a lokacin sarrafawa.

4. Tsarin ja na Core

1. Dole ne a yi maƙalar tare da aƙalla rataye rataye guda ɗaya akan saman sama da ƙasa don sauƙaƙe rarrabawa da haɗuwa.

2. Kasa na darjewa ya kamata a yankan trough, da lalacewa-resistant tsiri ya kamata a sanya a cikin 2 guda 8-12mm mafi girma daga kasa mold tushe surface don sauƙaƙe tsaftacewa na aluminum slag a lokacin samar.

3. Gilashin maɗaukaka ya kamata ya zama tsagi mai jurewa, wanda shine 45° tare da jagorar jan hankali.

4. Tsarin zamiya ya kamata ya zama mai sauƙi a cikin jagora da zamewa, barga a cikin motsi, tare da izinin 0.08--0.12MM.

5. Bayan an rufe gyare-gyare, ya kamata a danna magudanarwa da shingen kullewa da kyau, wurin hulɗar ba kasa da kashi biyu cikin uku ba, kuma yana da wani prestress.

If you'd like to speak to a member of the Anebon team for Aluminum Casting,CNC Machined Custom Service,CNC Turning Alloy, please get in touch at info@anebon.com

Lokacin aikawa: Fabrairu-25-2021