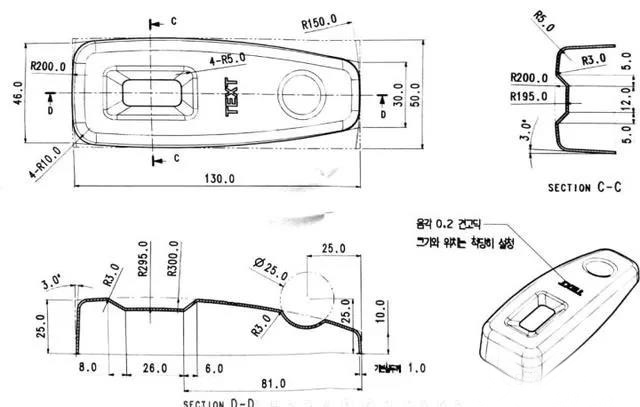

Tsarin yadda ake yin samfuri tare da fayilolin zane na 2D. Mai zuwa shine 2D:

Da farko, na ga irin wannan 2D. Idan ina so in yi samfuri, na fara bincika kuma in fayyace tunanina. A cewar ƙungiyar, Ina iya ganin kusan bangarori shida, sama da ƙasa, hagu da dama, gaba da baya.

1. Kasa-jirgin sama.

2. Sama mai lankwasa: saman yana buƙatar zana shi daban, kuma ana aiwatar da ƙayyadaddun abubuwan da suka danganci su ta hanyar sasheC-C da sashiD-D.

3. Hagu, dama, gaba da baya-jirgin sama: Akwai daftarin aiki a kan jirgin. A wannan yanayin, extrude + daftarin aiki gabaɗaya ana amfani dashi don zana. Hakanan zaka iya zana madaidaicin lanƙwasa kuma zana tare da umarnin saman daidai, amma tsarin yana da wahala.

Bayan an ƙaddara ra'ayin hoto na gaba ɗaya, duba cikakkun bayanai, galibi murabba'i da hoton da'irar, wanda ba ya shafar hoton gaba ɗaya, zana daban, kuma an kammala ra'ayin.

Mai zuwa shine ƙaddamarwa, da fatan za a duba:

Nasihu:

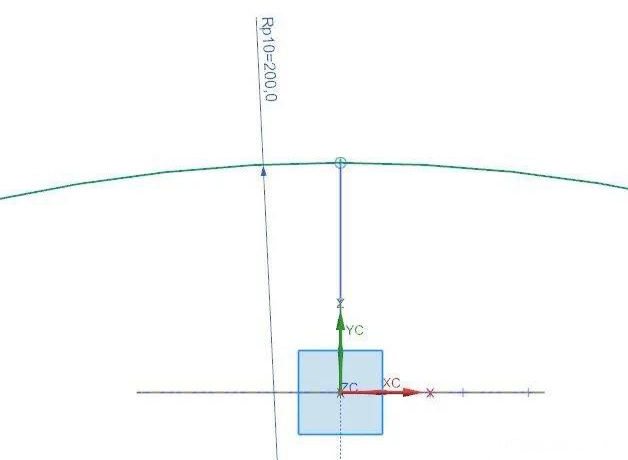

1. Haɓaka zaɓin matsayi na tsarin: gabaɗaya zaɓi wurin da wurin farawa na girma ya fi ko kuma tsakiyar siffa mai ma'ana. Idan ka kalli hoton, haɗin sashin C-C da DD shine mafi kyau.

2. Ƙwaƙwalwar ƙaramar da muke amfani da ita lokacin zana hotuna ya kamata a canza shi zuwa layi na taimako (layi mai tsinke) a cikin lokaci, wanda ke da mahimmanci ga zane-zane masu rikitarwa.

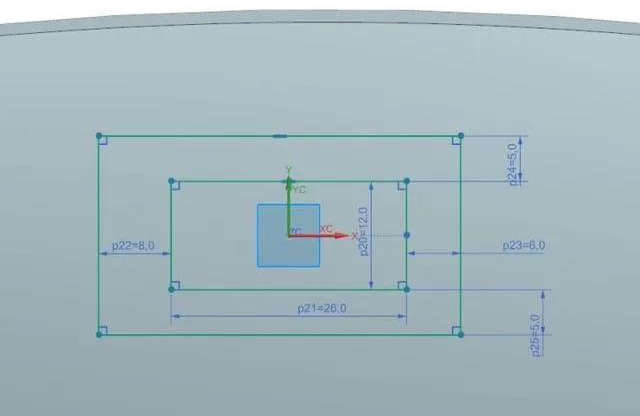

Asalin daidaitawa: sama da ƙasa daidaitacce, hagu da dama bisa ga sashe DD P7 =81+26/2.

Hoton zane a saman ƙasa ya cika.

Nasihu:

1. Siffar sama da ƙasa:

Mudubin baka na sama yana sauka

Wurin tsakiyar baka biyu na hagu da dama yana kan XC

2. Lokacin datsa lanƙwasa, kula da hankali ko akwai wasu gajerun layukan da suka rage a cikin sasanninta

3. Lokacin da maƙasudin ya kasance a kan madaidaiciyar layi, al'ada mafi kyau ita ce fara zaɓar madaidaiciyar layi, sannan kuma yana da sauri don zaɓar wurin.

Sashe

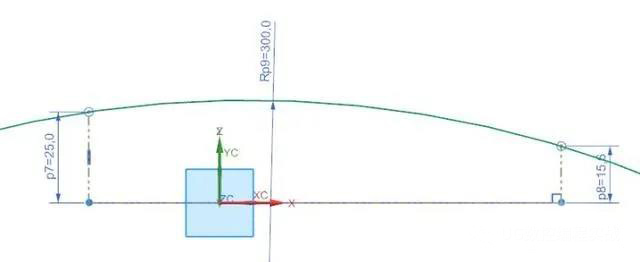

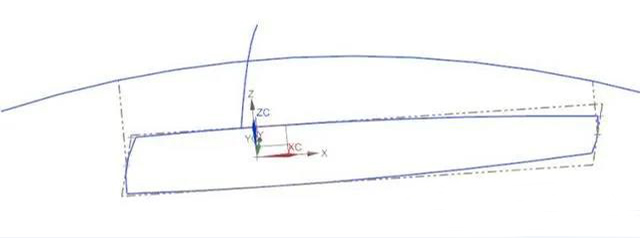

Samar da DD, saboda bayan an zaɓi tsarin haɗin gwiwarmu, Sashe na DD zai iya zaɓar jirgin sama na XZ kai tsaye

Nasihu:

Lokacin yin saman da ya dace, lanƙwan da aka zana gabaɗaya yana ɗan tsayi kaɗan fiye da girman, kuma saman da aka yi daga baya zai zama ɗan girma kaɗan, wanda ya dace da ƙari da raguwa daidai. Sai dai takurawa girman.

Sashe

Samar da CC, saboda bayan an zaɓi tsarin haɗin gwiwarmu, Sashe na CC na iya zaɓar jirgin YZ kai tsaye.

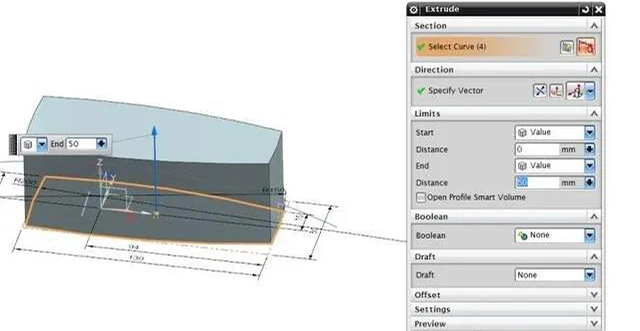

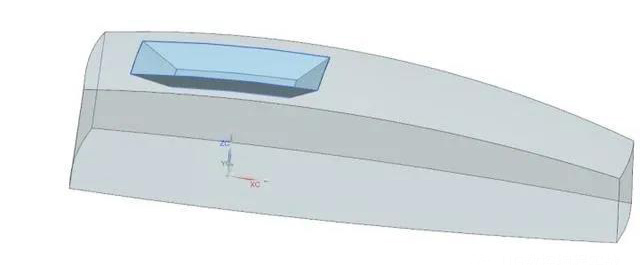

Fitar da daskararrun babban jikin mu.

Nasihu:

Tsayin Extrude ya kamata ya zama mafi girma fiye da mafi girman ma'auni na samfurin gwargwadon yiwuwar (mafi girman girman alama shine 25, kuma tsayi a nan shine 50), don sauƙaƙe ayyukan ƙari da raguwa daidai. Sai dai takurawa girman.

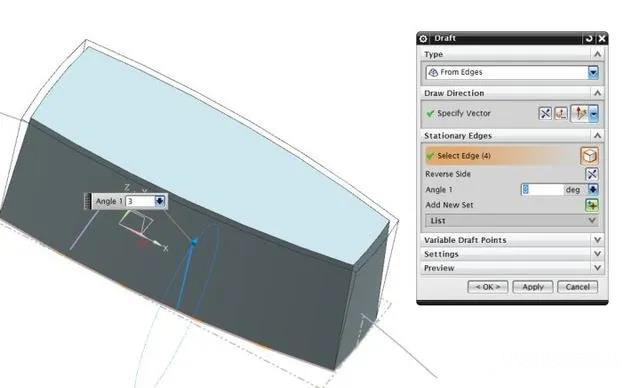

Zana kusurwar tambayar.

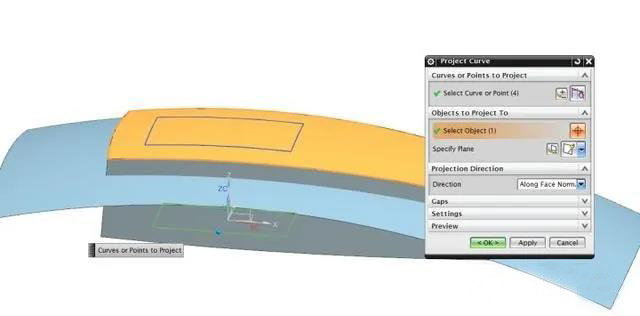

An zana takurawa a saman saman

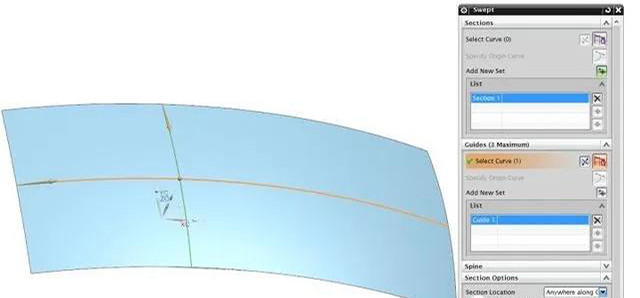

Samar da saman saman: yi amfani da sharer umarni.

Nasihu:

A cikin akwatin umarni a hannun dama, duba Siffar Tsare-tsaren kamar yadda zai yiwu, don haka saman da aka samar ya fi dacewa da ƙuntatawa na lanƙwasa da muka zana.

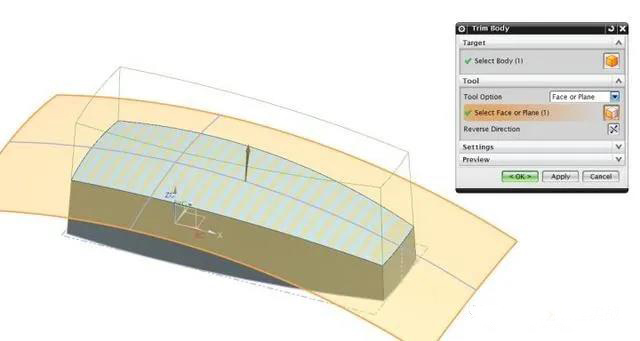

Yanke babban jikin mu tare da saman da muka share don kammala ainihin hoton saman saman.

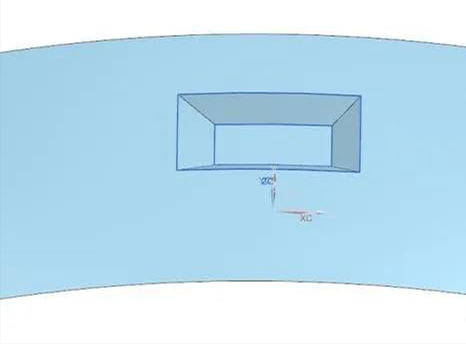

Zana cikakken hoton murabba'in a gefen hagu na samfurin. Dangane da Sashe na CC da sashe na DD, hoton murabba'in da aka yi hasashe a saman ƙasa na iya ƙuntatawa. Hoton da ke sama zane ne da aka zana akan jirgin XY.

Girman sashe CC R200, R195 da sashin DD

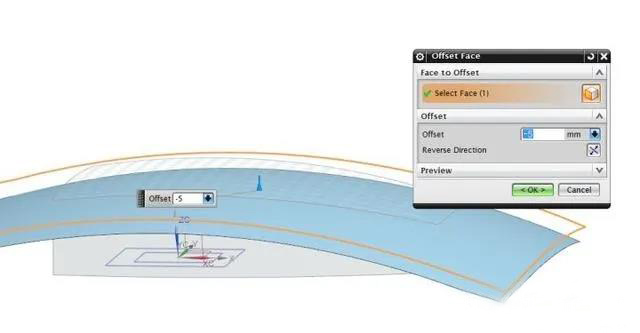

Don R300, R295, muna amfani da kashe-5 akan saman saman don kammala saman tare da ƙaramin R, kuma sakamakon da aka gama yana nunawa a cikin adadi a ƙasa.

Yi aikin mafi girman rectangular wanda aka zana a ƙasan saman saman R300.

Yi aikin ƙaramin rectangular wanda aka zana a ƙasan saman saman R295.

Hoton mai ƙarfi bayan ɓoye babban jiki yana nunawa a cikin adadi.

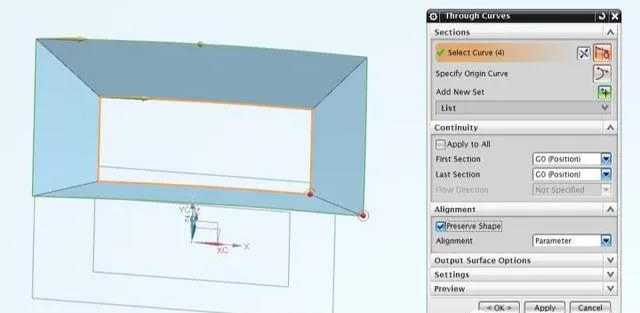

Ta hanyar

Curve yana zana gangara huɗu a cikin adadi na sama.

Nasihu:

1. Lura cewa wurin farawa da shugabanci na sama da ƙananan rectangles dole ne su kasance iri ɗaya, in ba haka ba za a karkatar da zane-zane.

2. Dole ne a zaɓi siffar da aka adana, in ba haka ba ba za a sami wani yanki tsakanin kowane fuska biyu ba, sauyawa mai laushi, kuma babu wata hanya ta chamfer.

Duba Tsare siffa a hagu, kuma cire alamar Preserve a dama

siffar, don Allah kula da bambanci a kusurwa.

Nuna saman wanda nisan sa ya kasance -5 a baya.

Bayan datsa fuskokin sabbin sassa huɗu da aka ƙirƙira, kamar yadda aka nuna a cikin adadi na sama.

Bayan dinka jiragen biyu, canza fuskar gaba daya.

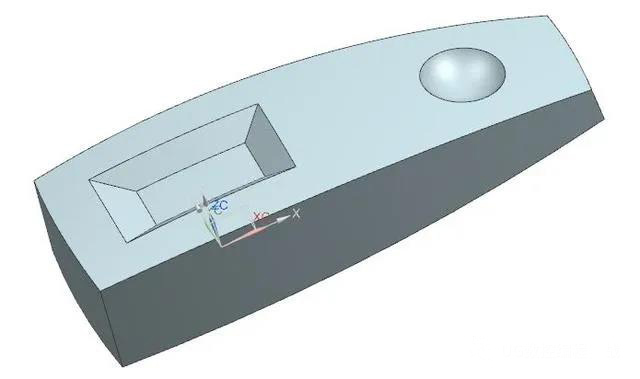

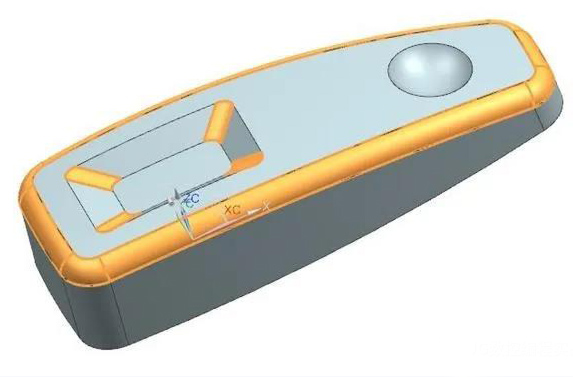

Yana nuna ƙaƙƙarfan jikin samfurin, zaku iya ganin cikakken hoton kamar yadda aka nuna a sama

Faci gaba dayan saman bayan an dinka zuwa babban jiki.

Zana tsakiyar filin a dama kuma saka aya.

Zaɓi wurin da muka yiwa alama da girman kuma zana yanki.

Yi ragi na Boolean akan jiki da yanki.

Samun cikakken hoton mu, kawai chamfering da harsashi.

Nasihu:

1. Zaɓin tsari na chamfering da harsashi: Dubi radius na harsashi da kaurin bangon harsashi ya fi girma, fara fara girma. Don wannan adadi, chamfer sasanninta ya ɗan fi girma, kuma fara fara chamfer.

2. Chamfers da yawa tare da radiyo daban-daban, an zana su a cikin tsari daga babba zuwa ƙarami

Lura cewa lokacin zabar iyakar sashi, alkiblar gefen abun ya dogara akan ko ragowar kayan yana waje ko a cikin lanƙwasa.

If you'd like to speak to a member of the Anebon team, please get in touch at info@anebon.com

Lokacin aikawa: Maris-10-2021